Perovskite Solar Cells Achieve High Efficiency in the Lab

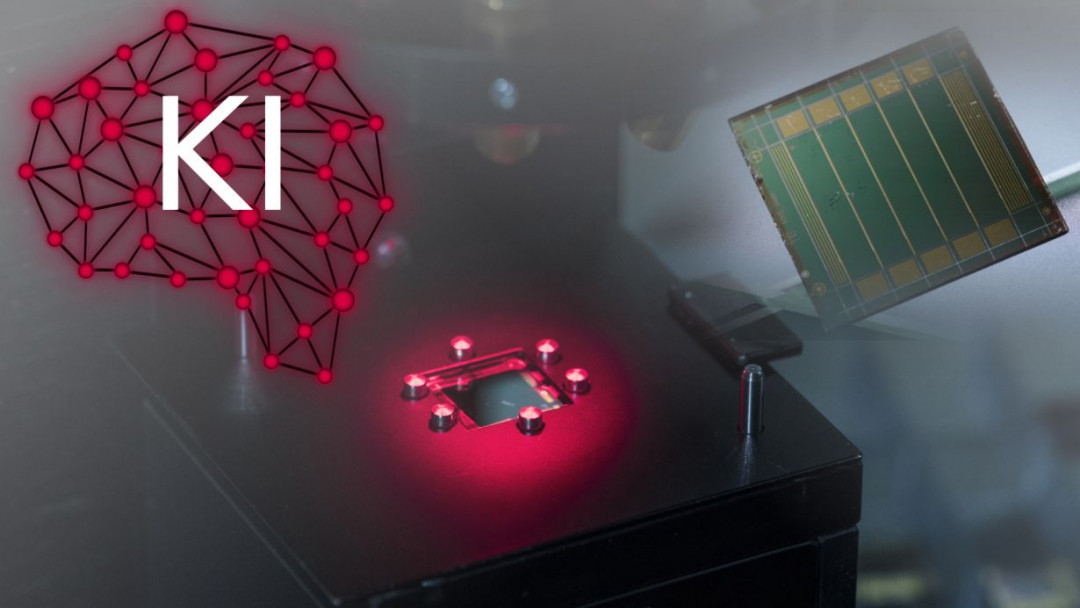

Perovskite solar cells demonstrate high efficiency in converting solar energy into electricity in laboratory settings. When combined with silicon solar cells, they could become the next generation of photovoltaics. Researchers at the Karlsruhe Institute of Technology (KIT) have now shown that machine learning (ML) is a key tool for improving the measurement techniques required for the commercial production of perovskite solar cells. Their study has been published in the journal Energy and Environmental Science (DOI: 10.1039/D4EE03445G).

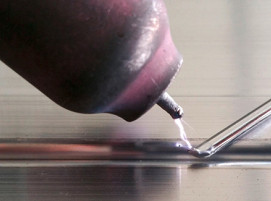

Photovoltaics is a key technology for a low-carbon energy supply. Solar cells made from perovskite semiconductor layers already exhibit very high efficiencies and can be manufactured cost-effectively. Additionally, this technology can be designed to be thin and flexible. “Perovskite photovoltaics are on the brink of commercialization. However, challenges remain regarding long-term stability and scaling up to large areas,” says Professor Ulrich Wilhelm Paetzold, who conducts research at the Institute of Microstructure Technology and the Light Technology Institute (LTI) at KIT. “In our study, we demonstrate that machine learning is crucial for improving the monitoring of perovskite thin-film formation required for industrial production,” the physicist explains.

Using deep learning – a machine learning method that leverages neural networks – KIT researchers were able to quickly and accurately predict the material properties and efficiencies of solar cells, even beyond laboratory scales.

A Step Toward Industrial Applicability

“Based on measurement data collected during production, machine learning can identify process errors before the solar cells are completed. No additional investigation methods are needed,” says Felix Laufer, a research associate at LTI and the study’s lead author. “The speed and performance of this method significantly improve data analysis, enabling tasks that would otherwise be difficult to manage.”

Analyzing a novel dataset documenting the formation of perovskite thin films, the researchers used deep learning to precisely correlate process data with target variables such as energy conversion efficiency.

“Perovskite photovoltaics have the potential to revolutionize the photovoltaic market,” says Paetzold, who heads the Next Generation Photovoltaics division at LTI. “We demonstrate how process fluctuations can be quantitatively analyzed by extending characterization methods with machine learning techniques. This ensures high material quality and film uniformity over large areas and multiple production batches. This is a critical step toward industrial applicability,” the scientist emphasizes.

(Source: Karlsruher Institue for Technologie)

Schlagworte

PhotovoltaicResearchResearch PaperSolar