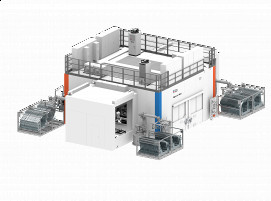

Trumpf is launched the new generation of its TruLaser Weld 5000 automated laser welding machine at Blechexpo in Stuttgarat, Germany. Compared to the previous series, the machine can be set up much quicker and easier. In addition, thanks to the new TeachLine Touch mode, users can optimize their welding programmes directly on the machine's screen. The operator uses a touch gesture to move the welding points to the desired position on the actual component.

The increased user-friendliness adds value, especially for small batch sizes, as users can get to the first component in their series much faster. The user sets the welding programme in advance – while the machine is in operation – by means of the TruTops Weld offline programming software. “The combination of the new TeachLine Touch mode and TruTops Weld enables simple and intuitive operation of the machine – without any loss of productivity and without the need for in-depth programming knowledge,” says Trumpf Product Manager Moritz Berger.

New energy-efficient laser

The TruLaser Weld 5000 is also particularly energy-efficient, as the integrated next-generation TruFiber laser consumes around 20 % less energy. At the same time, welding depths can be increased by 5 %. The new design of the protective cabin with higher doors also ensures that larger components can be transported into the machine more easily.

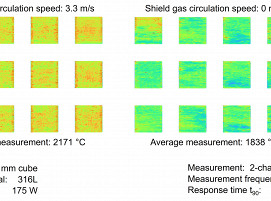

Quality weld seams

On the TruLaser Weld 5000, Trumpf’s BrightLine Scan function ensures weld seam quality for aluminium as well as higher gap-bridging capability. The technology also enables higher weld seam strength, for example in lap seams. BrightLine Scan also expands the fields of application for optics, allowing users not only to weld components, but also to clean and engrave them – without having to retool the machine. Trumpf has developed the BrightLine Weld function to prevent unwanted spatter on fixtures, components and optics. Using a special laser light cable, more even distribution of power is achieved.

Seamless integration into smart factory

The new machine can be seamlessly integrated into a smart factory, thanks to suitable interfaces for automated loading and unloading solutions or automated guided vehicles (AGVs). In addition, the “Smart View” service allows live machine data to be clearly evaluated, enabling users to identify errors at an early stage and exploit optimization potential. The machine can also be customized to meet specific requirements. For example, it is possible to integrate specialized loading and unloading systems for XXL components, such as rail-based shuttle systems. Other welding optics, sensors or beam sources are also possible.

Economical for small series and mass production

With the TruLaser Weld 5000, users can choose between a latest-generation TruFiber laser with 3 kW, 6 kW, or 9 kW of laser power. Almost all common materials can be processed with the machine, in particular structural steel, stainless steel, copper or aluminum.

(Source: Trumpf Laser- und Systemtechnik GmbH)

Schlagworte

AluminiumCopperITLaserLaser Beam WeldingSmall Batch SizeSmall SeriesSmart FactorySteelSystem SolutionsWelding