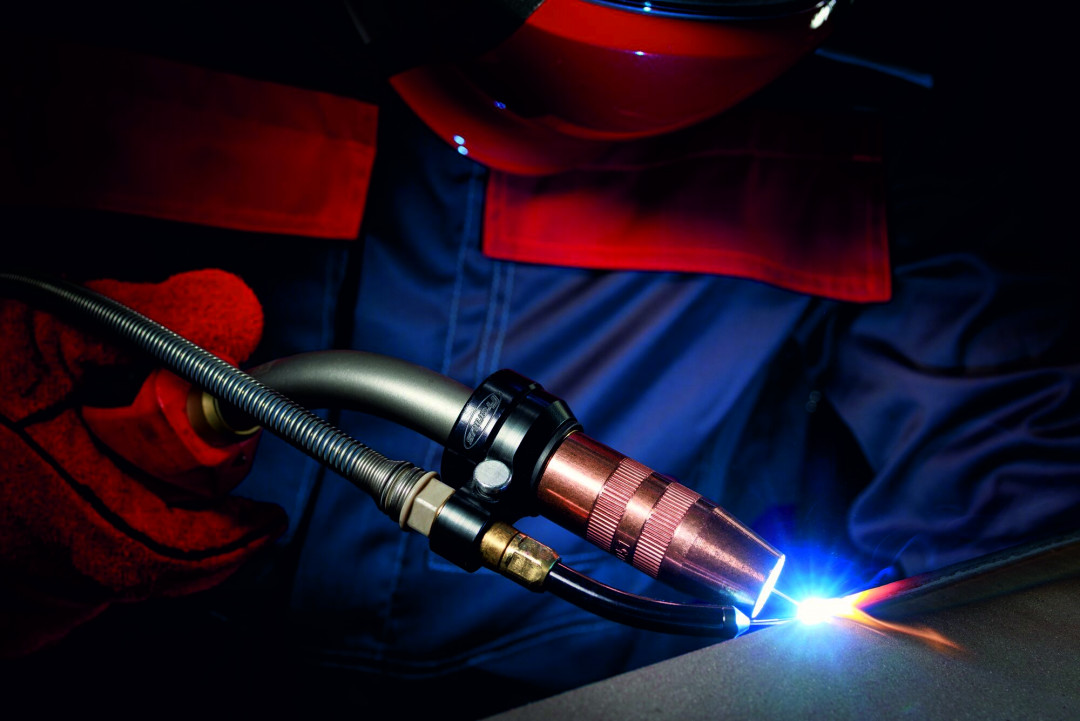

Long welds pose challenges even for experienced welders: consistent speed and precise torch guidance are crucial for the quality of the seam – but at the same time difficult and above all strenuous to maintain over longer distances. To address this issue, the Velo Velocity Assistant from Fronius enables precise control of welding speed during manual welding. It supports a wide range of applications, especially where long, even welds are required – for example, in areas of commercial transportation, heavy-duty machinery, steel construction or apparatus engineering. Velo is suitable for thin-sheet applications as well as for thick-sheet welding in steel, CrNi or high-strength steel.

A step forward in manual welding

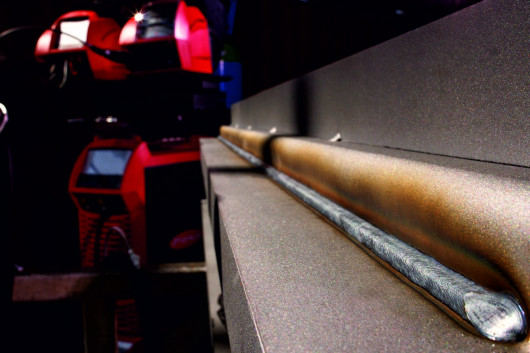

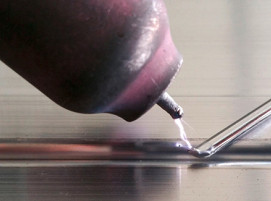

At the heart of Velo is a second wire – the so-called Velo wire, which works without an arc and without an additional gas feed. This wire touches the workpiece in its solid state and generates a forward movement through friction. The travel speed of the Velo wire determines the welding speed. The Velo wire keeps the distance between the workpiece and the contact tip constant and “pushes” the torch along the seam edge, notch or chamfer without any special seam preparation. Throughout the process, the Velo wire adds only a minimal amount of material to the seam: the wire consumption corresponds exactly to the seam length.

“If you allow yourself to relinquish some control, you can now produce perfect welds in manual welding at unprecedented speed by simply holding the torch,” explains Franziska Eichhorn, Strategic Product Manager at Fronius International. “Test users confirm noticeably less strain and a significant increase in precision and welding quality.”

Suitable for all skill levels

While beginners quickly achieve high-quality welds thanks to the supportive guidance, professionals benefit from the relief provided for long or complex welding tasks. Cramping and fatigue are a thing of the past and the seam quality remains consistent. Under certain conditions, Velo can achieve welding speeds comparable to those of robotic welding.

Simple upgrade of existing system

Velo is compatible with existing TPS/i devices from 320 A and iWave Multiprocess PRO systems and can be easily retrofitted. Requirements are

- the wirefeeder for the Velo wire

- a suitable torch adapter with Velo wire feeding system

- the corresponding software activation

Integration into existing systems is quick and easy.

Focus on ergonomics and flexibility

The Velo holder can be rotated 360° without tools and locks securely into place. If accessibility is restricted, the Velo system components can be simply unclipped from the holder and set to one side. Thanks to its flexibility, the system is suitable for all positions – even for pipe welds with 360° seams or multi-layer applications. A large operating range is ensured through the five-meter-long Velo wire feeding system. The system is activated directly on the welding torch and can be deactivated at any time if required in order to switch flexibly between manual and assisted guidance.

(Source: Fronius International GmbH)

Schlagworte

MAGMIGSteel IndustryTorchTransportationWeldWeld SeamWeldingWelding TorchWireWorkplace Safety