You will find the company at the fair in Hall 3, Stand 3C63.

You will find the company at the fair in Hall 3, Stand 3C63.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

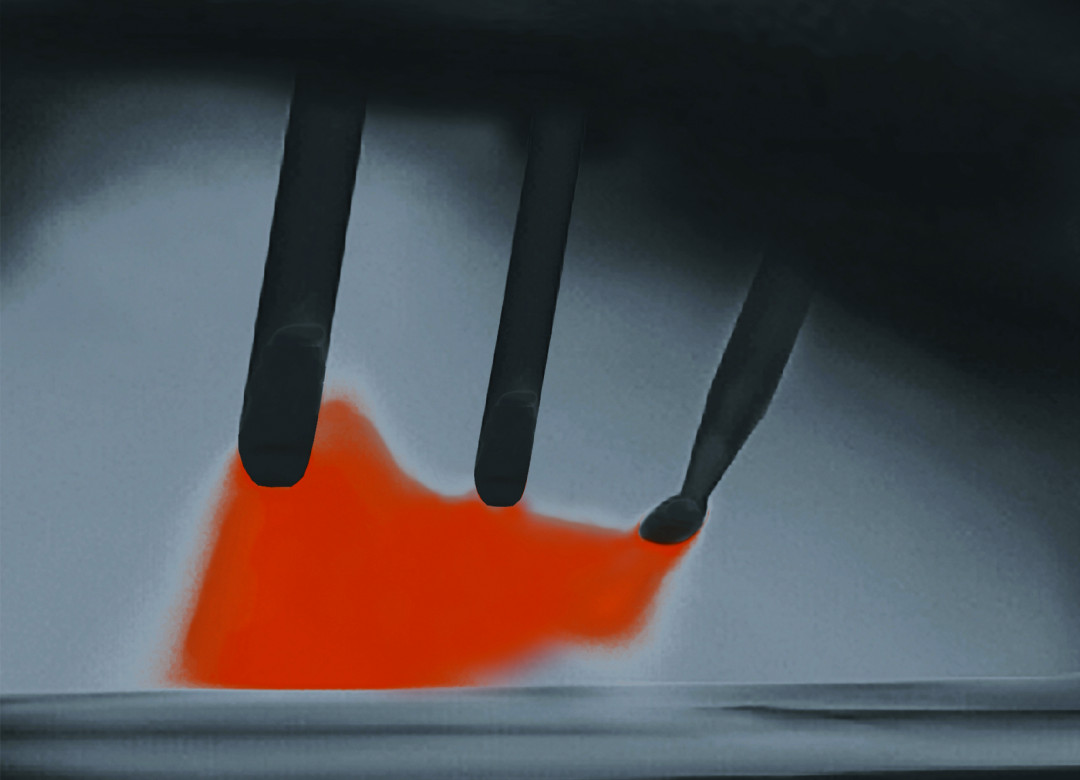

Carl Cloos Schweisstechnik will present its Tandem+ MIG/MAG welding process with a 3-wire-system, achieving up to 30 % higher deposition rates than the previous Tandem Weld technology.

3-wire-process

Tandem+ was specially developed for applications with high demands on deposition rate and process reliability. This high-capacity process combines two independent arcs with a filler wire in a molten pool for maximum process stability. It is suitable for large-volume welding in sectors such as rail vehicle construction, wind power, steel and boiler construction and the construction machinery industry.

Upgrade for existing systems

Existing welding systems with tandem technology can be converted to Tandem+ with an upgrade kit.

Premiere at SCHWEISSEN & SCHNEIDEN 2025

In a live demonstration within a fully automated robot cell, visitors will experience first-hand how the 3-wire process works in practice.

Tandem+ at a glance:

- Up to 30 % higher deposition rate

- 3-wire process for maximum flexibility

- Less welding layers, shorter welding times

- Reduced cleaning and programming effort

- Retrofit of existing systems possible

(Carl Cloos Schweisstechnik GmbH)

Schlagworte

EventFairMAGMIGSteelTrade FairVehicle ConstructionWeldingWind PowerWire