AMADA WELD TECH offers Jupiter Laser Welding System for Battery Tab Welding

Successful laser manufacturing processes depend in large part, on the successful integration of laser systems. Designers need to develop systems where the motion control, laser, software, and tooling work together and are integrated into a machine that supports the desired process flow. Putting all the pieces together can be challenging.

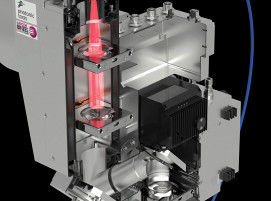

Amada Weld Tech highlights its Jupiter Laser Welding System, a semi-automatic production system for welding battery modules for use in electric vehicles, power tools, energy storage and military battery module applications. The Jupiter is ideal for battery modules measuring up to 300 x 300 x 300 millimetres, with typical weights up to 20 kilograms. It is particularly suitable for thin- to medium thickness battery tabs made from nickel, Hilumin® (nickel plated steel), aluminium, copper, and brass.

Easy to focus and position

The Jupiter system can be equipped with several lasers and a laser weld head with fixed optics or a galvo (scanner). Its motorized XY table and Z-axis make it easy to focus on and position the parts being welded. PLC control results in ease of usage and reliability in production environments.

Safe to operate

The Jupiter Laser Welding System features a Class 1 laser welding enclosure for battery tab welding, which is safe to operate in a regular production environment. An integrated combustion suppression unit (CSU) safeguards both the system and the operator. Whilst integrated fume extraction takes care of keeping the enclosure clean and safe from contamination.

Power fibre laser

The Jupiter comes with a 500W average power fibre laser in the near infrared (NIR) wavelength range. A manually operated front door provides manual loading, whilst an automatically operated side door may be used for robotic or inline loading. The integrated down-holder provides maximum joint quality and process traceability by maintaining good part to part contact.

(Source: Press Release Amada Weld Tech)

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)