KUKA, a globally active automation group, and Kleusberg, a specialist in modular construction and mobile space systems, have announced their cooperation. The goal of the collaboration is to modernize production at the Kleusberg plant near Halle (Saale), Germany, and automate it using KUKA robots. Starting in 2027, floor and ceiling frames for modular construction will be manufactured using a flexible, robot-based welding system.

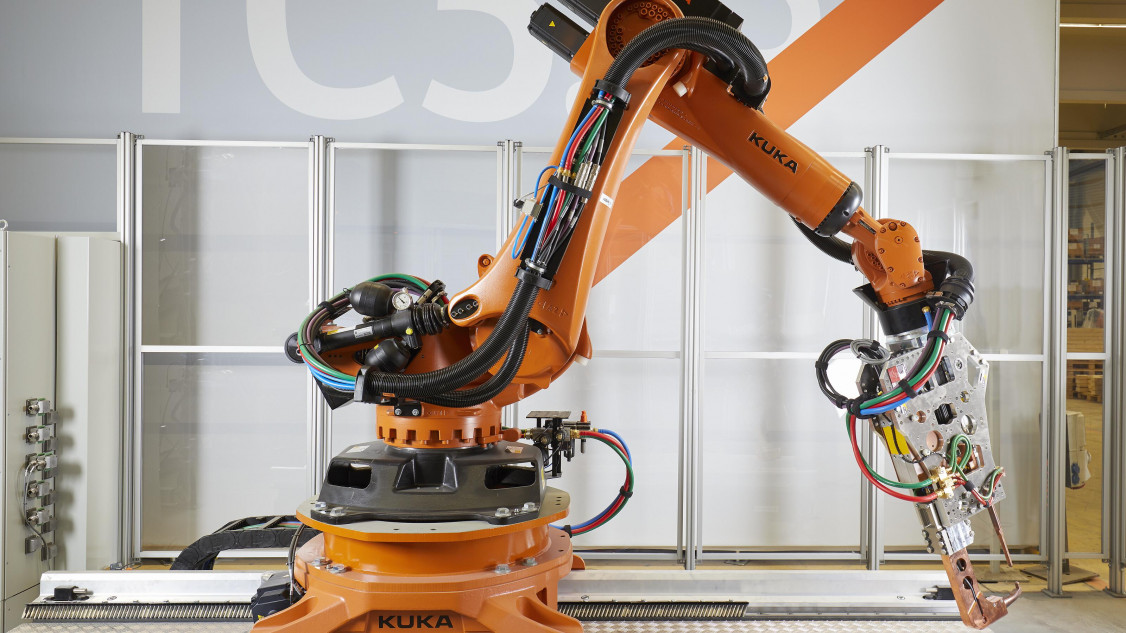

This turnkey system, supplied by KUKA, uses state-of-the-art automation technology to

enable nearly fully automated production. The heart of the system consists of five robots programmed independently of the product, allowing for customized frame production. The

more than 1,000 m2 production area enables efficient manufacturing. Each week, over 2,000 m of 2D frames are expected to be welded together.

“In addition to increasing efficiency, improving working conditions played a significant role in the decision to automate, aiming to reduce health risks for employees caused by physically demanding postures. Furthermore, new technically oriented job roles are being created,” says Oliver Hartmann, Managing Director of Modular Construction at Kleusberg.

Modular construction

Modular construction is a modern building method using industrially prefabricated room modules based on a modular principle. This type of construction, also known as system construction or serial construction, typically uses steel frame structures but can also be realized with wooden modules. Serial and industrial prefabrication in the factory, combined with digital processes, not only offers cost and planning reliability but also enables

significantly faster completion of construction projects compared to conventional methods.

(Source: KUKA Group)

Schlagworte

AerospaceAutomationManufacturingProcessingRobotRoboticsSpot WeldingWelding