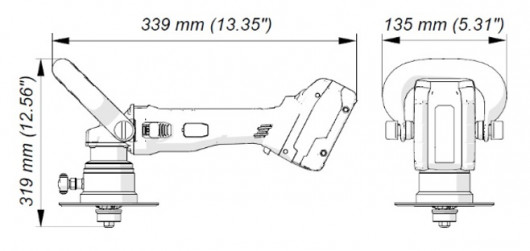

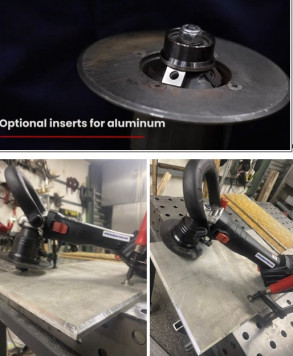

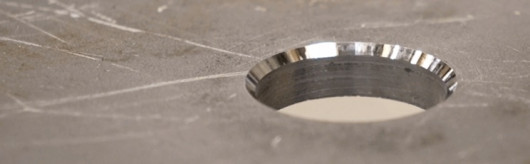

Promotech expands its line of portable bevelling tools with the BM-6 Battery – a lightweight, compact cordless solution for bevelling flat plates, pipes and curved profiles. This handy tool produces bevels up to 6 mm wide on steel and aluminium, even on materials as thin as 4 mm.

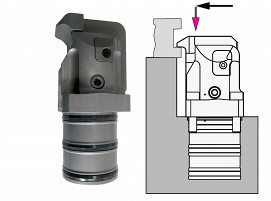

From bevelling and countersinking to rounding and prepping weld joints, the BM-6 Battery Cordless Compact Beveller is a versatile, easy-to-use solution for workshop and field applications. Designed for adaptability, the BM-6 Battery enables users to create bevels at either 30° or 45°, depending on the milling head selected. A single 45° head supports both V bevels and radiused edges.

Cordless solution powered by CAS

The BM-6 Battery is a cordless beveller powered by a CAS battery system, engineered to deliver mobility and performance, thanks to its compact size and cable-free operation.

Cordless mobility powered by CAS

The BM-6 Battery is powered by the 18V CAS battery. CAS (Cordless Alliance System) is a cross-manufacturer battery pack system of over 40 power tool brands. Everything fits everything: machines, batteries and chargers.

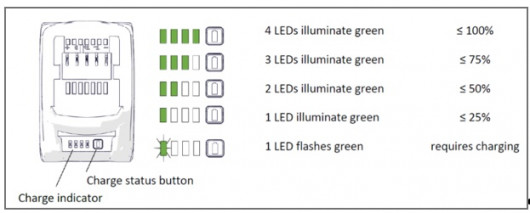

Battery management

CAS Battery that goes with BM-6 Battery beveller features intelligent battery management, both thermal and electrical. It safeguards optimal battery performance during operation and charging. Battery control system offers real-time diagnostics and data monitoring, preventing situations of:

- too low and too high voltage

- too low and too high temperature

- failure of the temperature sensor

- internal battery failure

Charging with patented air cooled technology

While charging, the CAS battery is gently air cooled to maintain the required temperature. It extends overall battery life and allows for up to 30 % faster charge times.

More information on the BM-6 Battery

(Source: Promotech)

Schlagworte

AluminiumBatteryBattery ChargingBattery TechnologyBevelBevellerBevellingCuttingMachineMillingSteelWelding