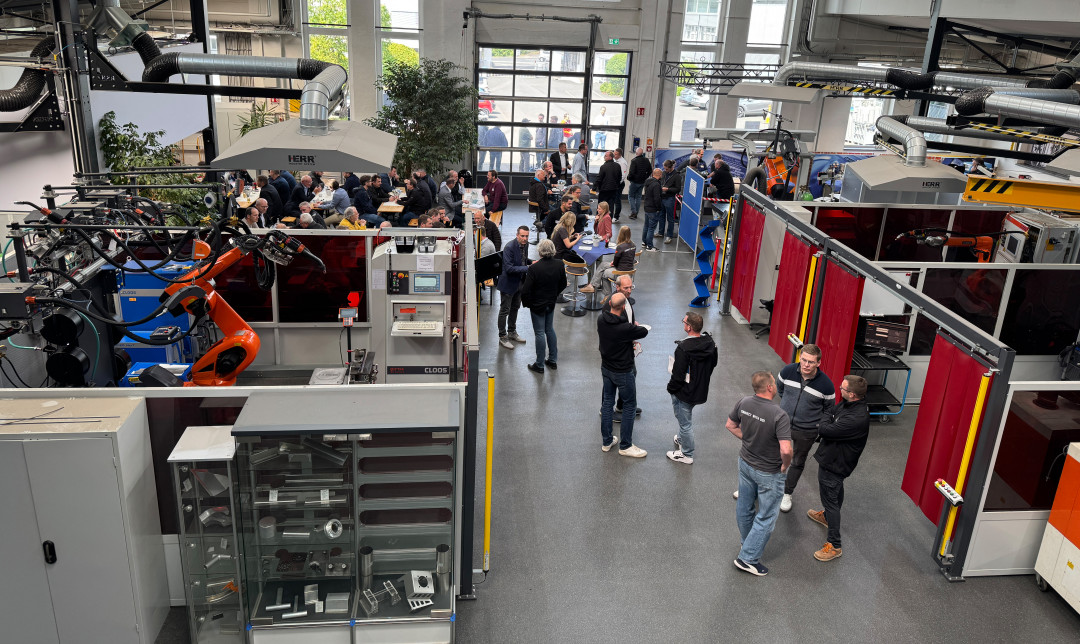

Carl Cloos Schweißtechnik held its annual customer conference, the Cloos Tech Day, on 8 May, 2025, under the motto Welding technology & automation: mastering challenges – smart solutions against skills shortages, for efficiency and quality. More than 120 participants from various industries took part in the event and used the opportunity to find out about the latest developments and solutions in welding technology and automation.

The event began in the morning at the Genusswerkstatt Haiger and continued in the afternoon at the Cloos headquarters in Haiger. After a welcoming address by Stephan Pittner, CEO of the Cloos Group, Prof. Dr. Jutta Rump, Director of the IBE Ludwigshafen, gave a presentation on the New normal in the world of work. Practical success stories were presented later in the morning, including a lecture on retrofitting as the key to sustainability, efficiency and competitiveness as well as best practice examples for modern welding production.

In the afternoon, parallel thematic blocks were held focusing on current challenges and solutions in welding technology and automation. Topics included: artificial intelligence and digitalisation with practical examples of the Cloos digitisation platforms Qnect and C-Gate. Automated grinding technology, ways to increase efficiency in steel construction and innovative welding processes were also on the event schedule. Visitors also had the opportunity to participate in a tour of the company to gain a personal impression of the vertical range of manufacture at Cloos. The event concluded with an informal get-together, where attendees engaged in lively discussions and networked in a relaxed setting.

(Source: Carl Cloos Schweißtechnik GmbH)

Schlagworte

AutomationEventRetrofittingSustainabilitySymposiumWelding