Hydrogen in joining technology – a well-established or an emerging market?

The debate about transitioning to a hydrogen economy has been and continues to be intense. While in the 1990s the use of hydrogen was seen as a visionary material of the future, much has changed since then. Today the focus is more on practical issues relating to its large-scale use, particularly in terms of economic viability. Not only climate change, but also issues related to the geopolitical situation and supply security characterise the feasibility of long-term development in business and industry.

Use of hydrogen is frequently discussed, particularly in reference to the transportation sector, which is currently responsible for approximately 20 per cent of Germany‘s CO2 emissions. The idea of a „fuel“ whose handling would be similar to the operation of classic petrol stations is attractive, especially considering its much higher energy density compared to current battery storage systems. Both the use of fuel cells and hydrogen combustion engines appear to be technically market-ready. However, battery vehicles are currently the focus of the market and development worldwide, particularly due to their lower system complexity and high efficiency. Charging options are growing far faster than the sparse number of hydrogen refuelling stations.

Hydrogen is also attracting a lot of attention as a conceivable storage medium for surplus energy from renewable energy sources (power-to-gas). There is certainly potential here, especially to handle strong fluctuations in supply volume, as can be the case locally with wind and solar energy. The industrial sector is neglected in the public debate, particularly the steel and chemical industries. Compared to the transportation and energy sectors, there are currently few alternatives other than hydrogen not based on fossil fuels. These industries continue to be of considerable importance for the German economy, a source of numerous jobs and globally competitive expertise, which has advanced innovation, particularly in mechanical and plant engineering. The needs of these sectors must be given special consideration when enabling the use of hydrogen produced with renewable energy (green hydrogen).

If we look at the future prospects for hydrogen demand and proposed production projects, we can assume there will be a supply gap for some time to come, which will have to be covered by imports. This is not necessarily a disadvantage. In contrast to the production of fossil fuels, decentralised energy generation and hydrogen production can in principle be economically viable. And global trade without the energy sector is hard to imagine.

So what role does joining technology play in regard to hydrogen? As a manufacturing technology, it enables economical construction of the entire, sometimes highly specialised, plant technology and infrastructure required for the hydrogen economy. Already developed disciplines, such as manufacture of process engineering systems or steel towers for wind turbine construction, will retain their essential role with modified process approaches. However, joining technology will once again determine how (and in what economic way) individual parts are turned into a complete object.

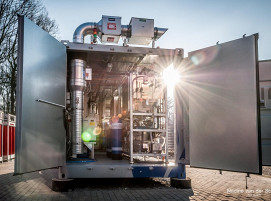

New challenges arise in the field of large-scale hydrogen production. The manufacture of electrolysers is particularly worth mentioning. They are generally designed as complex multi-material constructions, which place a variety of demands on joining processes. In addition, distribution infrastructure will also play a major role, which can only be fulfilled by suitable joining technology.

The chemical industry has many years of on-going experience in both the materials used and their various applications in the hydrogen economy. What is new here is the degree of effort, as a transition to mass production of system components for electrolysers, distribution grids, extraction points and fuel cells must take place. And here, economic viability is often determined by the scalability of many joining processes. Industry can provide answers in co-operation with research. A number of the known joining processes offer performance alternatives that have not been utilised to-date due to less evidence of economic benefit. The required solutions often do not have to be completely redeveloped, but can be transferred to a new application. An example is pipeline repair under operating pressure. In the future, hydrogen will be in contact with the pipe wall heated by the welding process instead of natural gas. In many other areas, the old has to be rethought.

It is already obvious that the importance of green hydrogen for Germany‘s industry will increase tremendously, as the emissions trading regime agreed upon in the Kyoto Protocol will lead to a sharp rise in the cost of fossil fuel consumption worldwide. The growing attractiveness of using hydrogen will incentivise joining technology to meet the future demand. The entire joining technology industry should address this challenge now, as competitiveness and economic viability will determine transition speed to the hydrogen economy.

Dr.-Ing. Rahul Sharma (IWE) Head of Arc Welding Department, Welding and Joining Institute, RWTH Aachen University