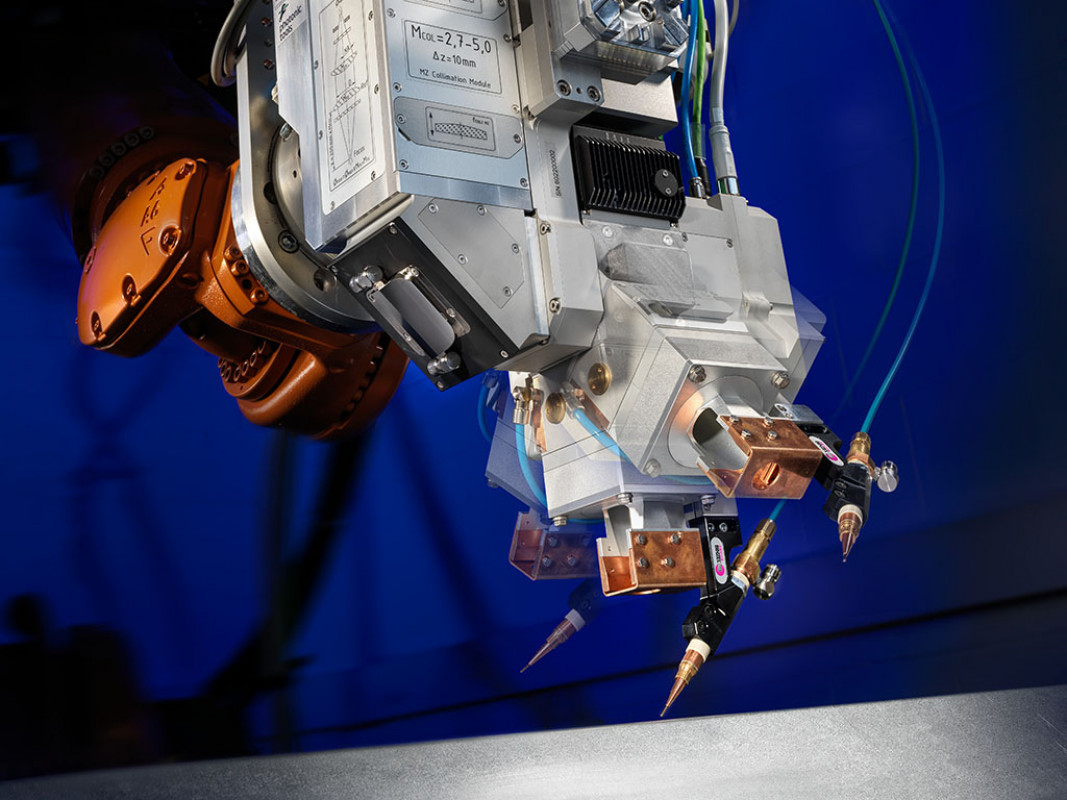

Time is money when welding at high speeds, e.g. in automotive engineering, rail vehicle construction or transportation vehicle construction. The tactile laser optics MPH Tactile from Abicor Binzel is a system that can cover a wide range of applications – without time-consuming and costly conversions.

Smart modular design for maximum flexibility

- Only one optical system for imaging scales from 2.7 to 5.0

- High system safety due to integrated status monitoring and recording of all optical elements (lenses, mirrors, protective glasses) in real time

- Maximum system availability due to revolutionary maintenance and repair concept

- Can be integrated into any fieldbus system thanks to a control system that can be configured to suit the user's needs

- Excellent process reliability through simple integration of different systems for process visualisation and process monitoring

- Easily expandable with various accessories

When developing the MPH Tactile laser optics, the focus was on flexibility in application instead of diversity and a wide range of variants. This concept means that you need to keep fewer replacement systems in stock. Together with the user-friendly maintenance and repair concept, the MPH Tactile sets a new standard in tactile laser joining.

Further information can be found here:

(Source: Abicor Binzel Schweisstechnik GmbH & Co. KG)

Schlagworte

Automotive EngieneeringLaser OpticsRail Vehicle ConstructionTactile Laser WeldingWelding