Mastering complexity through digitalization

Digitalisation in production is not a short-term trend, in fact it is gaining momentum. Continuously recording and analyzing relevant data leads to significant knowledge gains in order to better understand interrelationships and interactions and control complex production processes more efficiently. However, digitalization is also a challenge and requires a high degree of flexibility in the utilized production technology. This also applies to ultrasonic welding systems. In order to exploit the potential of digitalization both today and in the future, hardware and software must be coordinated so that data from a wide variety of sources can be recorded and made available in real time. At the same time, the use of the ultrasonic welding system should remain manageable, be as simple as possible for the user and flexibly integrated into the respective production system.

The Swiss Telsonic Group has been represented with industrial ultrasonic systems in Europe, America and Asia since 1966. The introduction of the TelsoFlex technology platform laid the foundation for comprehensive digitalization in ultrasonic welding, on which the “Weld Control by TelsoAssist” function modules are based. The software connects the hardware of the ultrasonic systems for metal or plastic welding with the user interfaces and offers the necessary flexibility and stability to record a wide range of data relating to the welding process and make it available in real time. It thus provides a reliable foundation for both current functionalities and future data-driven functions.

More than just data

But data alone is not everything. That‘s why the ultrasonic specialists have created TelsoAssist, a toolbox that extracts practical information from the collected data. The corresponding function packages, for example for error prevention, traceability or planning service work, are constantly developed further to support the utilization of the ultrasonic systems. The focus is on lowering operating and maintenance costs while ensuring a consistent user experience. Operation should remain consistent, even when new, improved functions are added.

Simplicity instead of complexity as the key to success

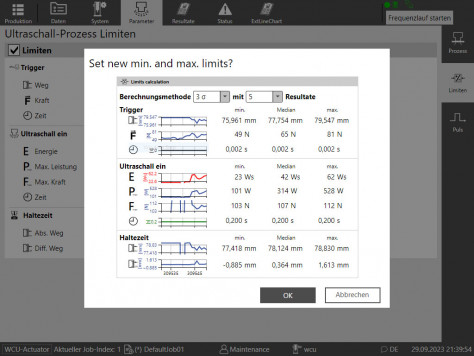

A shortage of skilled labour and the resulting increased need to relieve personnel resources of unproductive tasks are important issues not only in the automotive industry. In addition, there are increasing demands on quality management for the production of safety-relevant products. TelsoAssist already offers practical support in this area. For instance, the Commissioning Log tool helps verify that the system is operating properly. During operation, monitoring functions detect impermissible deviations at an early stage. To this end, current measured values are continuously compared with validated, regurlarly updated reference data to prevent errors from occurring in the first place.

The ultrasonic systems can also be configured easily and securely via a web interface and integrated into systems. The MES Connector simplifies the connection of Telsonic systems to customer production systems (MES). Users have the ability to customize the interface to their MES, enabling them to tailor their systems independently without depending on Telsonic. The MES Connector offers ready-made functions for reacting to events, recording orders, sending messages, creating logs and retrieving data. It is a JAVA open source software that runs parallel to the TelsoFlex software on the machine‘s PC. Users receive comprehensive support through the visualisation and monitoring of data and statuses as well as the logging of deviations. Workflows are designed to significantly reduce the familiarization period and, if necessary, assist with specific recommendations to continue production.

Further development

Through continuous development, more powerful functions, will be added and seamlessly integrated into the software and its user interface. New function modules are already being developed. Data processing will become increasingly differentiated and enable an overview and control of dynamic events through real-time data processing. Context-related visualisation helps to master complexity and only shows what is important at any given time.

(Source: Telsonic Press Release)

Schlagworte

CleaningCuttingPlastic WeldingSievingWelding