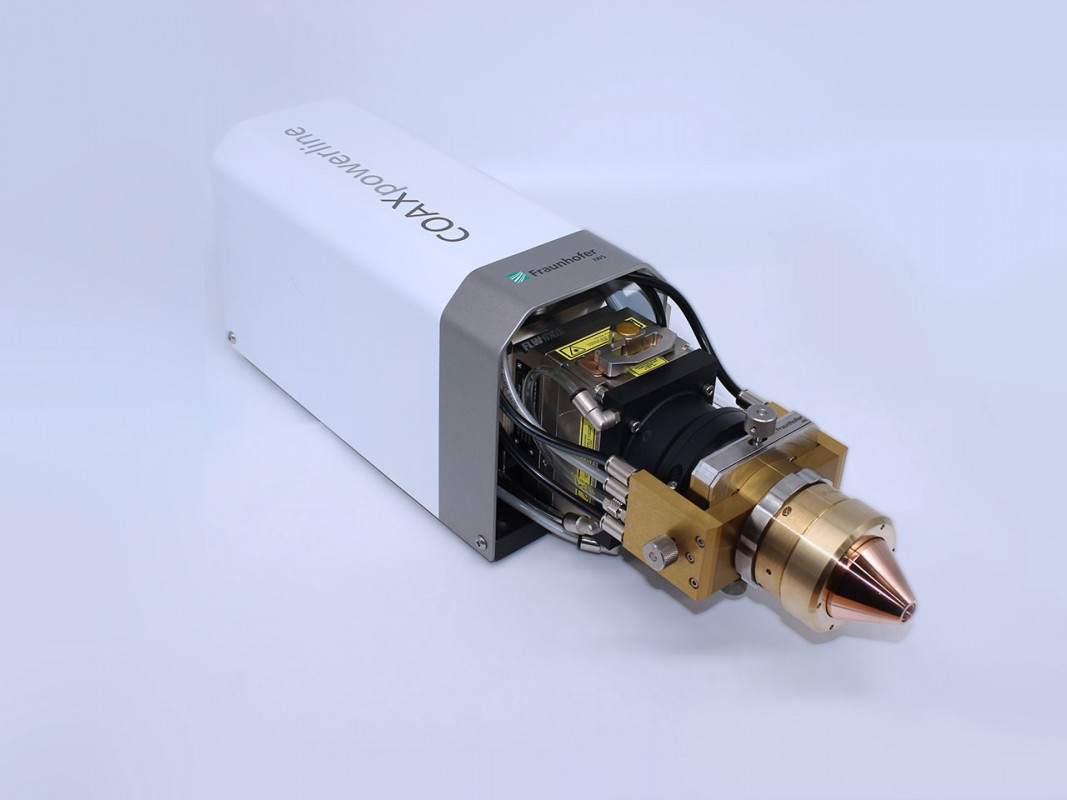

Line of modular processing heads for laser metal deposition with powder and wire

Laser cladding processes have long played a key role in the aerospace industry. This is because laser-based additive manufacturing offers the possibility of realizing complex component geometries, increasing product quality and setting oneself apart from competitors. High-performance processes, beam tools and machining heads that metallurgically combine different materials or generate structures are in demand. They can be used to functionalize surfaces, subsequently modify component designs or repair long-life assemblies instead of replacing them completely.

The “COAX“ system family provides the appropriate tools. It comprises a complete line of modular processing heads for laser cladding with powder and wire. For this purpose, the Fraunhofer IWS develops special coating heads that feed the material coaxially to the laser beam at the processing location and enable a direction-independent welding result. These systems are used in common laser systems and hybrid processing centers for additive manufacturing. Specially developed coating units are optimized for use in extreme conditions or confined spaces, while others are suitable for particularly fine structures or for high-quality materials such as titanium or high-entropy alloys.

(Source: Fraunhofer IWS Press Release)