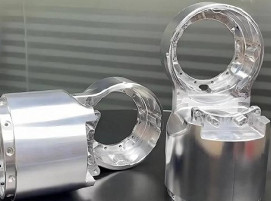

ABB has launched a new version of its Millmate Thickness Gauge (MTG) technology that brings precise aluminium thickness measurement to the final stages of the hot rolling process. The new MTG Box Gauge extends the performance of the MTG technology into hot rolling environments. MTG Box Gauge measures aluminium strip thickness below 8 mm at the tail end of hot rolling, where accurate data is crucial for ensuring product quality and production efficiency.

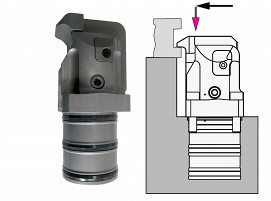

Protection against the demanding conditions encountered in hot rolling processes is ensured by a refined IP66 sealing that shields the interior sensor components from contact with emulsions used to manage friction and control temperatures during rolling.

The new design also features an optimized internal air flow that channels cool air toward heat sensitive electronic boards, while expelling warm air through the base of the unit. This can reduce the operating temperature of the transmitting coil by as much as 40°C, contributing to greater durability and improved efficiency.

MTG Box Gauge avoids the complexity and safety issues associated with X-ray systems and also enables precise single-side measurement without the need to mount sensors on both sides of the strip. This not only simplifies installation and maintenance but also reduces space requirements in the mill, making it valuable where access to the underside of the strip is limited. Unlike traditional thickness gauges that require recalibration for different aluminium alloys, the MTG Box Gauge delivers consistent, accurate results regardless of alloy type.

In October 2025, ABB received the “Manufacturer of the Year” award at the Instrumentation & Electronics Awards for helping the aluminium industry optimize production, reduce waste and achieve its decarbonization goals.

(Source: ABB Ltd.)

Schlagworte

AluminiumAluminumMeasuringMetalMilling