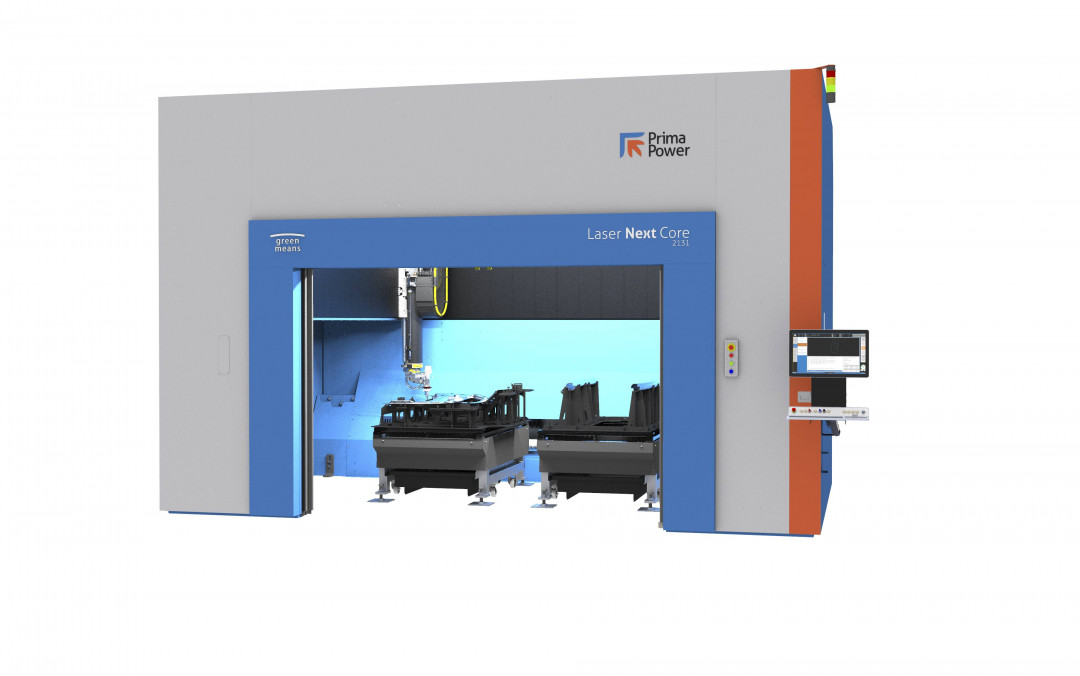

Prima Power, a supplier for sheet metal working manufacturing solutions, presents Laser Next Core, the newest addition to its 3D laser cutting range. Laser Next Core embodies the brand’s experience in 3D laser cutting, offering minimum cost-per-part, with versatility in the category and reduced footprint. Compact, cost-effective and easy to use, Laser Next Core is designed for job shops and flexible manufacturing environments seeking efficiency, versatility and fast return on investment, even for small batches and variable production mixes, without compromising precision or speed.

With axis strokes of 3,160 × 2,100 × 750 mm, parts of any size and geometry can be handled. It mantains quality even with frequent production changeovers, offering performance in both 2D and 3D cutting, as well as optional welding applications. Typical applications involve limited batch sizes (less than 1,000 parts per batch), where quick setup and production changeover are crucial.

Laser Next Core achieves minimum cost-per-part. This is accomplished through optimized fixed and running costs, reduced labour intervention, minimal maintenance effort, and limited gas and power consumption. Its outstanding versatility ensures maximum floor space efficiency with a working volume 58% larger in its class and a footprint 25 % smaller. Machine operation is further simplified by one-click programming, an intuitive HMI with graphical teach panel, and automatic head-offset compensation by local head axis, making high-performance 3D laser cutting easier and faster than ever.

Prima Power’s 3D Laser product family now includes four models, each addressing specific production requirements. The Laser Next Core 2131 offers the best versatility and minimum cost-per-part for flexible production, while the Laser Next 2141 stands out as a versatile in part size and application, balancing flexibility and productivity. The Laser Next 1530 and 2130 models are designed for high productivity in continuous production environments, even with material handling automation. Completing the range, the recently launched Giga Laser Next represents solution for large-scale, high-volume manufacturing, delivering maximum productivity in minimum space.

In line with the Evolve by Integration strategy, Prima Power 3D laser machines can be integrated into turnkey automated systems powered by the in-house Robotics Integration Unit. This modular platform manages 3D laser cutting, part handling, loading/unloading and quality check allowing manufacturers to level up their production in a seamless and adaptive flow that evolves with their needs.

(Source: Prima Power)

Schlagworte

AutomationBendingCuttingDrillingLaserManufacturingProductionPunchingRobotsSheet MetalSustainabilityWelding