InBatt Project Boosts Sodium Battery Efficiency

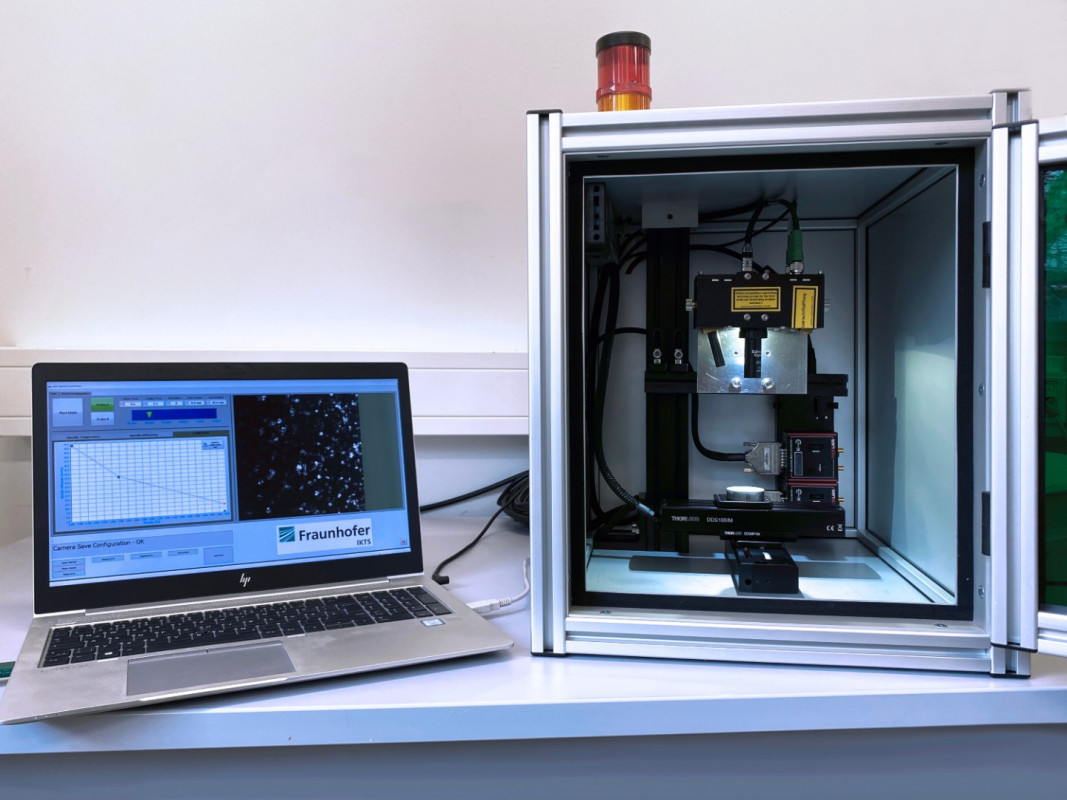

The use of sodium batteries promises both economic and ecological advantages. In order to further increase the efficiency in the production of the ceramic electrolyte, an inline quality control system will be developed as part of project InBatt. This system detects defects in the electrolyte at an early stage in the manufacturing process, thus helping to save material, energy and costs.

Sodium-ion batteries are attractive on several levels: They are based on sodium salts, which are readily available and recyclable. This means that they contain no or only very small amounts of critical raw materials. This is environmentally friendly and reduces material costs. Compared to conventional cells that use liquid or organic solvent-based electrolytes, using a solid electrolyte, high energy and power densities can be achieved, as well as exceptional safety levels. The production of these electrolytes is subject to high technical requirements to achieve a high production yield and stable quality.

The quality, i.e. the structural integrity of the ceramic electrolytes, determines the performance and lifespan of the battery cell. Condition monitoring of the ceramic electrolytes in the initial production phase helps to identify and discard defective components at an early stage. Currently used manual and visual quality control methods, such as optical inspection with cold light or He-leakage measurements, are not suitable for inline use and are especially not suitable for large production capacities.

Sensor detects smallest defects in the electrolyte

The BMBF-funded project InBatt aims to develop and qualify an optoelectronic LSP sensor for detecting manufacturing defects in non-sintered Na-ß"aluminum oxide electrolytes. It is based on laser speckle photometry (LSP), which is a measurement method extremely sensitive to small defect sizes. LSP has the potential to detect typical defects such as microscopic pores, microcracks, rough structures and local inhomogeneities in the material composition.

100 % inspection in real time before sintering

The LSP checks the resulting structure or the as-yet unsintered electrolyte for defects. By doing this, the energy-intensive sintering process can be avoided for damaged electrolytes. The material of the unsintered and defective electrolytes can be recycled and used to produce new electrolytes. Defective electrolytes are selected without contact and in real time. The 100 % inspection generates image data that is digitally evaluated to assess the electrolyte quality. This should further reduce scrap in battery cell production. By the end of the project period, a technology demonstrator will be realized and integrated into a production pilot plant.

(Source: Fraunhofer IKTS)

Schlagworte

BatteryBattery TechnologyResearch