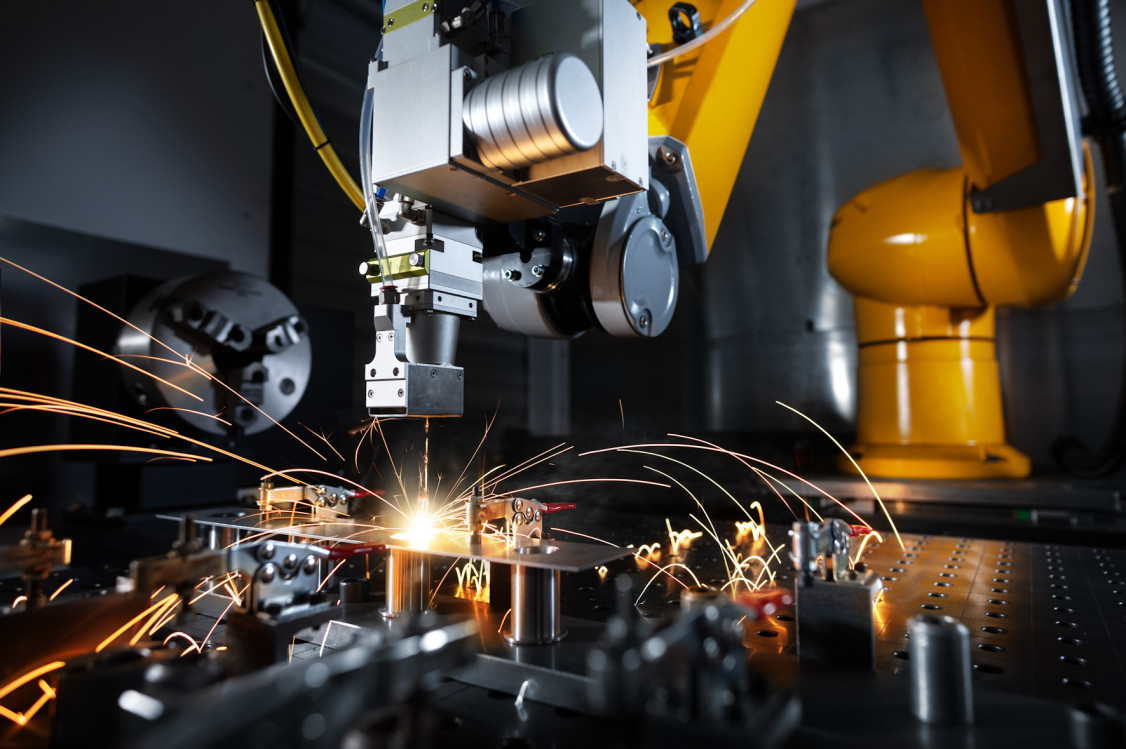

When the Italian metalworking company T.P.A., located in Brendola near Vicenza (Veneto), added laser beam welding to its portfolio of processes, the company didn’t do things halfway. It commissioned laser specialist L-Peak to design a fully automated robotic cell with a six-axis Stäubli robot serving two rotary tables. The result: utmost productivity and flexibility – and perfect laser welding results.

T.P.A. is a highly qualified and specialized contract manufacturer serving Northern Italy’s industrial sector. It supplies customized tube products, manifolds and housings to a customer base consisting mainly of manufacturers of heating and cooling systems such as heat exchangers. This means that many different products must be manufactured and many processes mastered. So flexibility is a must and the highest productivity is a prerequisite for competitiveness.

As Renato Cervellin, Managing Director of T.P.A. explains, “Our production ranges from medium to large series and we mostly process metal tubes and related products. We have a large fleet of machines, which allows us to carry out numerous mechanical processes. Our customer promise is to guarantee versatility, customization and bespoke solutions, even for non-standard items or special finishes, satisfying not only technical but also aesthetic and design needs.”

The Process of Choice: Automated Laser Beam Welding

In light of these commitments, the desire to add laser welding to the company’s core processes is fitting. “We were looking for a new welding solution to expand our processing methods and products and, where possible, try to replace traditional welding with a modern and more efficient system,” says Cervellin. “What we wanted was a versatile and efficient system designed for welding components of various sizes, from small to large pieces, and we were sure that a highly automated, robot based laser welding system would fulfill these requirements.”

For this project, T.P.A. approached L-Peak, an Italian company with a proven record in applying laser technologies – not only welding – in different industries. T.P.A. came to L-Peak with a clear concept, as Stefano Dalla Vecchia, President of L-Peak describes: “What they had in mind was a welding robot that is able to work in two independent cells.” The advantage of this concept is clear: While the robot is welding in one cell, the next workpiece can be set up in the other. This leads to maximum productivity with almost no downtime.

First Robotized Laser Beam Welding Cell

L-Peak had engineered and produced a wide range of laser-based automation solutions as well as a welding cell with a robot – but so far, no robotized laser welding cell. For this first, the company decided to collaborate with Stäubli Italy and use a Stäubli six-axis TX2-160L (the L denoting “long reach”) with a sophisticated laser welding head.

The Stäubli robot’s precision and long reach were key factors for this decision. “With its long arm, the robot is able to move the laser head around the workpiece with excellent precision and repeatability. This is crucial if you want to ensure a repeatable and efficient laser welding process,” explains Dalla Vecchia.

Because the robot uses a seventh (linear) axis, also supplied by Stäubli, it is able to weld workpieces in two separate and adjacent cells. This allows T.P.A. to make use of an additional advantage: The L-Peak engineers installed a door in the separation wall between the two cells which literally opens up the possibility for welding operations on very large components. This unique layout offers high flexibility and short lead time.

As Easy as Possible: Programming the Robot and Rotary Tables

The programs are created directly on the piece, with the help of a joystick and a PC which are directly integrated into the system. In this way, all the welding and arm movement tests can be carried out. Once the mode has been found, the operator only has to mount the piece on the jig and start the automatic work cycle. This is a feature that makes it very easy to adapt Stäubli robots to individual tasks – even when the application sets high standards in terms of precision, pace or complexity.

Another feature also contributes to the ease of operation and programming. Since an Ethercat master is used, no PLC is needed for the rotary table or other functions in the cell. Instead, the cells are controlled via the robot controller, and the seventh axis too. Thus the staff is able to manage all aspects of the cell with the robot controller, and all the data are available in one place – with the additional benefit of an OPC UA data-tocloud transfer.

Close Cooperation in Engineering and Installation

During the commissioning and installation of the cell in early 2024, all three parties cooperated closely. In the end, the machine was designed and built entirely by L-Peak personnel including software programming – despite the fact that this sophisticated welding station was the company’s first robot-based laser welding project. Renato Cervellin: “Stäubli’s support was fundamental, as they oversaw the entire programming and fine-tuning of the robotic arm and the special software of the plant – all carried out simultaneously with L-Peak technicians.” This approach was successful. “We could make full use of the double-cell robot from the start, without limitations. Stäubli offers an online assistance service, but to date, we have never used it.”

Prospects for the Future

Since its installation, the double-cell robotized laser welding system has proved to be very efficient. Renato Cervellin says, “So far, the system meets our expectations. However, we keep in touch with L-Peak for any future changes, additions or improvements that could make it even more efficient.”

Stefano Dalla Vecchia reveals some prospects: “In 2025, we will introduce a new function that increases the flexibility even further. And we are aiming at programming not only with the interface but also with a camera in order to process more complex parts and welding structures – with curves and special surfaces.”

Apart from any future improvements, Renato Cervellin and his team at T.P.A. are quite pleased with the new Stäubli welding robot and its double cells: “We have noticed a significant increase in speed compared to traditional welding, a much cleaner and more constant seam due to the robot’s precision and practically zero warping of the piece even on long welds.”

(Source: Stäubli Tec-Systems GmbH Robotics)

Schlagworte

AutomationIndustryLaserLaser BeamLaser Beam WeldingLaser WeldingMetal WorkMetalworkingRobotRoboticsTechnologyWeldingWelding Technology