Whether solvent or water-based cleaning, coarse, intermediate, and final cleaning or ultra-fine and high-purity cleaning, the tasks in parts cleaning have never been as varied as they are today. Ecoclean (Hall 10, Stand D36) will be presenting a complete product portfolio for these very different applications and requirements in the various industrial sectors. Information on the comprehensive range of contract cleaning, automation, and digitalization as well as on optimizing the energy and resource efficiency of cleaning processes will round off the trade fair presentation.

Today, component cleaning has to meet an enormous range of tasks and requirements. Not only do very different cleanliness specifications - from grease and/or particle-free to the removal of ultra-fine particulate contamination in the sub-micrometer range and nanolayers of residual film contamination - have to be met in a stable manner. Cleaning must also be carried out very economically and in a way that saves energy and resources. As a full-service provider of future-oriented, flexible, and resource-efficient solutions for industrial component cleaning, Ecoclean and UCM will be presenting a perfectly tailored range of products and services at this year's parts2clean (Hall 10, Stand D36) from October 7 to 9 in Stuttgart.

Optimally designed for the respective task

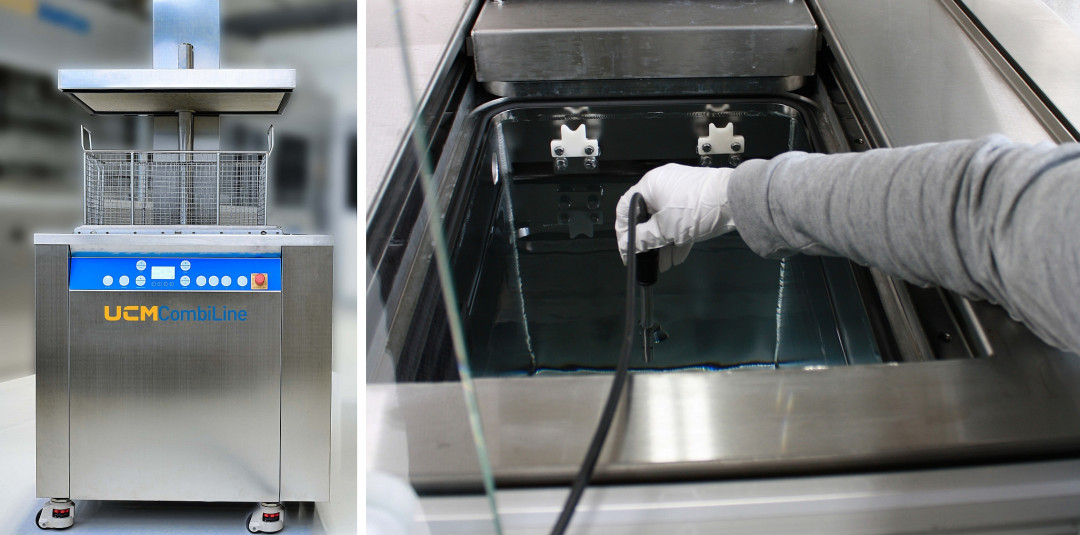

It includes modularly designed cleaning systems and customized special systems as well as application-specific process technologies, for example for spray, high-pressure, immersion, ultrasonic and plasma cleaning, steam degreasing, injection flood washing, pulsed pressure cleaning (PPC) and ultrasonic plus. This means that all tasks, from coarse to high-purity cleaning, can be performed not only stably, but also efficiently and in a resource-saving manner. Four cleaning systems from the wide range will be on show live. These include the new EcoCvario aqueous chamber system. It is equipped with PPC as standard, among other things, and can therefore handle even very demanding cleaning tasks reliably and economically. The cost-efficient and highly flexible EcoCcompact for solvent cleaning will be on show in the L version. The product family is available in three working chamber sizes and batch weights of up to 150 kg and can be easily converted from hydrocarbon to modified alcohol. Adapted to the cleanliness requirements, the compact plug and play systems can be equipped with all process technologies available for solvent cleaning and for use in high purity cleaning. With the UCMIndexLine, the system manufacturer is presenting a very compact rotary indexing system. Equipped with six cleaning and rinsing stations - with and without ultrasound or PPC - almost all processes for aqueous-based precision cleaning can be mapped. The system was designed for cleaning small and compact components, for example in medical technology, precision optics, precision mechanics and the jewelry and watchmaking industries. Ecoclean will also be exhibiting the UCMCombiLine, a modular ultrasonic cleaning system for low throughputs and high cleanliness requirements. The machine, which is available in several sizes for manual workstations, will also be used to demonstrate how the APM technology for validatable and contact-free measurement of ultrasonic frequency and power works.

Needs-based cleanliness as a service

This year's trade fair appearance will also focus on the significantly expanded range of contract cleaning services. This is carried out in the three Test and Service Centers equipped with the latest plant and process technology as well as connected laboratories for cleanliness tests. The range of services extends from classic parts cleaning through fine and precision cleaning to ultra-fine and high purity cleaning. Other topics at the stand include automation and digitalization solutions as well as the optimization of energy and resource efficiency.

(Source: EcoClean Group)

Schlagworte

AIApplicationARAutomationCarbonCleaningComponentsDEDDigitalizationDINEMOEnergyIndustryKINormOCTPlasmaPowerPPEResourcesTechnologyTrade Fair