When it comes to robotic welding systems, the debate over what drives productivity often centers on two core aspects: precision and accuracy versus uptime. A recent LinkedIn poll by Cloos North America highlighted a near-even split among respondents, underscoring the critical importance of both factors. But for manufacturers looking to automate, the question isn’t just which one matters more – it’s how to achieve a balance that aligns with your specific operational goals.

The case for precision and accuracy

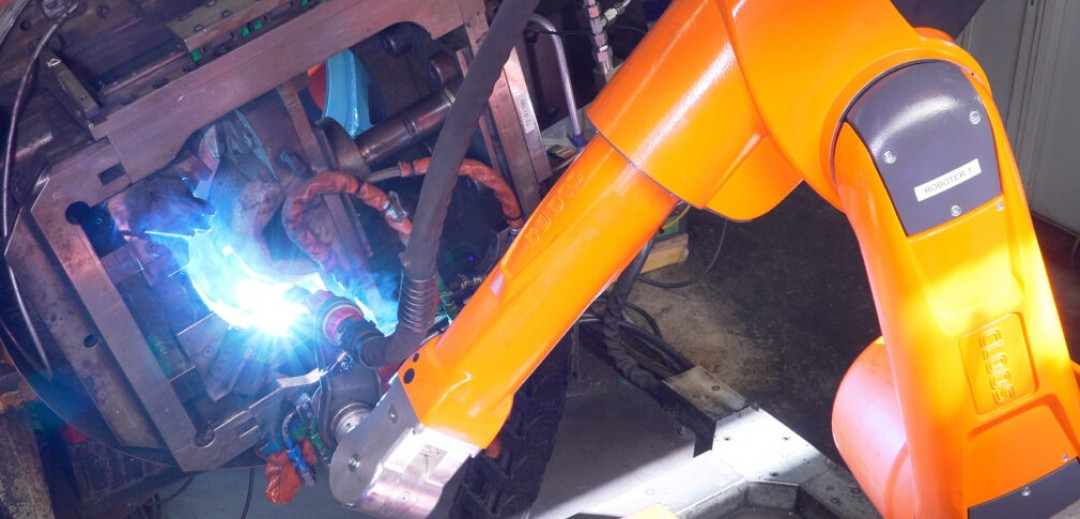

Precision and accuracy are the backbone of high-quality welds. In industries like agriculture, construction and heavy equipment manufacturing, weld quality isn’t just a nice-to-have – it’s essential. Imperfect welds can lead to downtime from rework, product failures or even safety risks. For manufacturers, a robotic system that delivers repeatable, precise welds can dramatically reduce waste and ensure customer satisfaction.

When evaluating a robotic welding system for precision, consider these questions:

- What is the system’s ability to adapt to different joint geometries?

- Does the system include features like seam tracking or adaptive welding technologies?

- How does the system manage welding spatter or distortion?

Cloos addresses these concerns by integrating advanced welding processes and programming flexibility into its systems. This ensures that even the most complex welds are executed with consistent quality, every time.

The Power of uptime

On the other side of the coin, uptime directly impacts throughput and productivity. A robotic system with best-in-class precision isn’t much help if it’s down for maintenance or repairs. For manufacturers facing tight deadlines or labor shortages, high uptime ensures a reliable and consistent workflow.

Questions to ask your vendor about uptime include:

- How long can the system typically operate before needing repairs or experiencing a breakdown?

- Are maintenance intervals and requirements clearly defined?

- How quickly are replacement parts and service technicians available?

At Cloos, uptime is a priority. With durable German engineering and localized support across North America, the aim to minimize downtime through robust design, easy-to-service components, and fast technical assistance.

Finding the right balance

For manufacturers exploring robotic welding for the first time, the real key is to strike a balance between precision and uptime. The best systems are those that align with your specific operational needs while addressing both factors effectively. Cloos by approaches automation from a welder’s perspective, offering tailored solutions that bring productivity without compromising quality.

(Source: Cloos North America)

Schlagworte

Robot WeldingRoboticsRobotsWelding