Innovation and Value in Welding Helmets

In this interview series, experts from 3M Speedglas, Gagnef (Sweden), a subsidiary of 3M Deutschland, provide insights into the world of welding helmets. They focus on product development, feedback from users and the worldwide market of welding equipment.

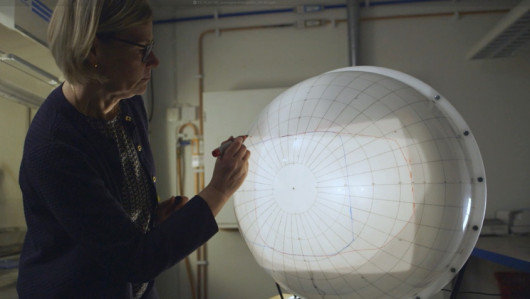

The next generation of welding helmets is driven by optics and electronics as well as by the question of what information is useful to show. Nichlas Sjöselius, 3M R&D-Manager, and Kristina Magnusson, 3M Division Scientist, explain how they evaluate new technologies in structured test phases, what role data and usability play and where they see the next development steps for filter and helmet.

What does the future hold for the development of welding filters?

Kristina Magnusson: I think there are different scenarios ahead – such as AI integration and a broader trend towards using more protective equipment that needs to fit and work together. The ultimate goal is to create a helmet that welders not only need but want to wear, while feeling completely comfortable.

With technologies such as AI in mind, do you intend to use and integrate them into the welding helmet?

Magnusson: I would say everyone is working with AI. The real question is what form it will take. Of course, we are considering how it can become a natural part of the tools we use in our research, for example in programming and in analysis.

Nichlas Sjöselius: AI will become an increasingly natural part of our research. When it comes to integrating AI into the helmet, we will focus on leveraging whatever best supports welders’ needs. In that sense, AI will be part of the work, but we will not add something and simply label it AI feature.

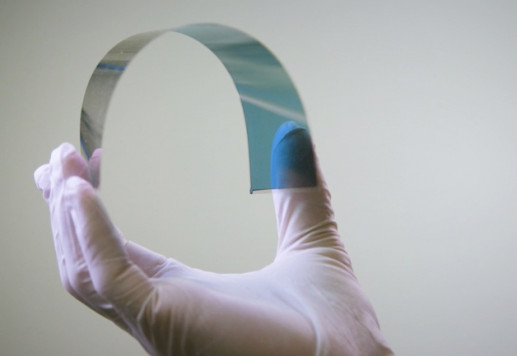

Currently, it is not possible to display information on the shield because its pixel density is too low. Is there a trend towards developing a filter with a higher pixel?

Magnusson: It is possible, but it comes with both advantages and challenges.

Sjöselius: It is one thing to suggest building a darkening filter with multiple layers, but a different challenge lies in the optics – presenting information positioned very close to the eyes. In fact, readability often decreases when content is too close. This means an optical solution is required to create the perception of distance. However, integrating such a solution into a practical design remains a challenge. Another critical aspect is how to guide and position the light. During welding, we already have a very bright spot, and any misdirected or amplified light would compromise functionality. That means it is not sufficient to add another layer, appropriate optical solutions are required to ensure usability. In addition to this challenge, there is also the question of meaningful content: even if the capability existed, what should be displayed? Data from a welding machine? Process-generated metrics? A camera feed? There are plenty of ideas, but they still need to be proven, and the key point is that cannot be integrated easily.

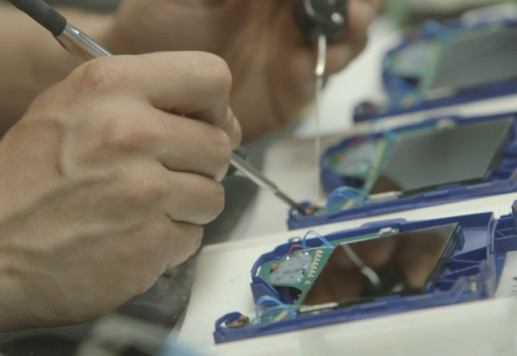

In field testing, it often took a long time for welders to embrace features like the TAP function to switch between different filter modes. Is there a vision to integrate more features like this, meaning more electronic functions and devices, into the helmet?

Sjöselius: With the connectivity that connects the welding helmet with an app, we can provide data. If you look at other wearables, they typically operate on the same principle: collecting extensive data about the user, depending on the type of device. In most cases, this data is personal. Even if it is stored in a cloud, it would be the user’s choice If, however, a company mandated such data collection, hesitation would likely increase. This is the balancing act we must manage. Adding features that collect data about welders – such as their activities, conditions, or even well-being – introduces sensitive information. It’s one thing if you’re self-employed and the decision is yours. But in a corporate setting, the question becomes: does the employer gain access to this data, including potential health information?

That is why this is an area where we would take very cautious, small steps. It is certainly interesting and we can provide technical possibilities, but ultimately it would have to be up to the user what is enabled and who can access what. In practice, it may also vary by worksite or local regulations.

In your development process, welders are not just end users but active sources of input through interviews, prototypes and field trials. How does communication work in practice? Do you, as the R&D team, stay in direct contact with welders?

Sjöselius: We rely on our application engineers to capture data. They are based around the world and support us whenever we need to gather input from the field. They follow a defined set of questions and we have a structured, certified process to evaluate that feedback. In the evaluation our application engineers play a key role as well. They belong to the R&D organisation, but they build a bridge within the company. They are the ones who continuously capture feedback from the field and help us bring it back into development.

Do application engineers help generate new ideas for development?

Sjöselius: Sometimes they bring back ideas and information they have picked up in the field. They follow a structured process for data collection, focusing not on proposed solutions but on understanding what welders want and need. Often, the right solution is not obvious. If someone says, “I need a yellow cap”, the next questions are: why does it need to be yellow? Why a cap at all? Digging deeper may reveal that the real need is visibility.

We focus on understanding the ‘why’ behind requests, because asking only, “What do you need?” often leads to perceived solutions rather than addressing the actual problem. The best outcome is identifying common needs – ideally those shared broadly across markets – which then become the starting point for development.

In terms of needs, do you quantify these kinds of needs? And do most of the requests come from Europe or do they come from other parts of the world?

Sjöselius: We tend to receive the most input where we have the strongest presence, simply because that is where feedback is most frequent. Europe plays a key role, as it is where we were founded, but we strive to maintain a global perspective. Interestingly, many fundamental needs turn out to be similar, even when you might expect significant differences.

3M products are sold in Europe and in countries on other continents, let’s take India as an example. Is it the same product or is the version for India different?

Sjöselius: Producing multiple versions is costly, so we try to capture the global needs. Sometimes we do create versions for different markets because there are different rules and different markings required. in some cases, market-specific versions are necessary due to differing regulations and labelling requirements.

Thank you for the conversation.

Schlagworte

AIApplication EngineersAuto Darkening FilterDevelopmentField TrialsPersonal Protective EquipmentPrototypesR&D-TeamSafety Requirements SpecificationTAP FunctionTechnologyWeldersWelding ApplicationWelding filterWelding Helmet