Acoustic emissions expose whether a laser process runs steadily or drifts off course. Fraunhofer IWS develops acoustic monitoring systems that evaluate laser machining directly and instantly. The goal: robust, economical process control to interpret sound emissions in real time and detect deviations immediately. The Dresden Institute showcases a market-ready module at Laser World of Photonics 2025 (June 24 through 27, Munich, Germany) while expanding the approach to laser welding and cutting applications.

Quality assurance in laser micromachining often involves delays, technical effort and complex post-processing. Typical structures feature micro- and submicron dimensions, requiring time-consuming microscopic inspection. Fraunhofer IWS now provides an industry-oriented alternative: a new acoustic monitoring module analyzes sound emissions generated during processing, assesses quality in real time, and visualizes anomalies – without removing the part from the machine.

Acoustics as a data source: real-time evaluation during the process

The system uses robust semiconductor microphones to capture sound emissions, a local evaluation unit and a neural network trained on real-quality data. It breaks the signals into frequency components and extracts key parameters such as amplitude, duration and pulse shape. These flow into an AI-based analysis that reliably classifies the process state as stable, deviating or faulty. Feedback occurs instantly and independently of additional sensors.

A standout feature is acoustic imaging. The system generates a two-dimensional map of the structured surface based on the spatial sound emissions distribution. This acoustic image mirrors conventional surface inspection – without external metrology, purely from process data. Irregularities such as contamination, misalignment or uneven ablation appear clearly and allow documentation. “We wanted a solution that evaluates process quality right at the machine – without sample extraction or lab measurement,” says Tobias Steege, Group Manager for Systems Engineering and Sensing at Fraunhofer IWS. “Our acoustic analysis does not replace microscopic inspection but enables robust, economical in-line control for every single part.”

Quality assurance in laser micromachining often involves delays, technical effort, and complex post-processing. Typical structures feature micro- and submicron dimensions, requiring time-consuming microscopic inspection. Fraunhofer IWS now provides an industry-oriented alternative: a new acoustic monitoring module analyzes sound emissions generated during processing, assesses quality in real time and visualizes anomalies – without removing the part from the machine.

Compact integration, cost-efficient operation

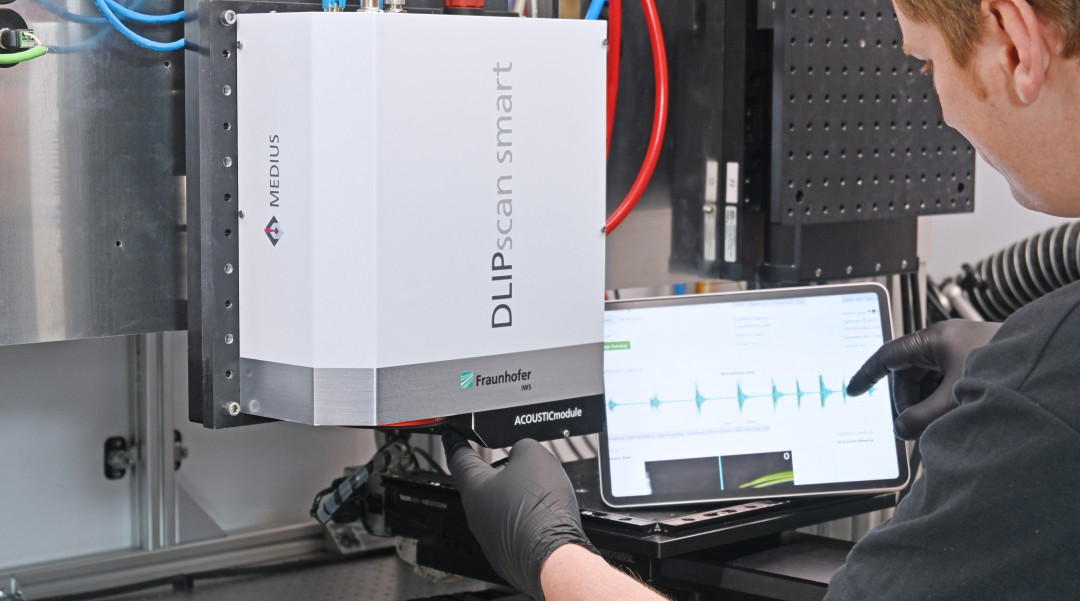

The monitoring module comes as a plug-and-play solution for industrial use. It features standardized Ethernet interfaces (TCP/IP, REST), needs no external cloud, and connects to standard machine controls. A modular design and use of semiconductor components significantly reduce system costs compared to conventional acoustic monitoring. This makes precise, inline-capable process control viable even for small production volumes. “The system runs out of the box – no special hardware, no external data link, just a network connection to the machine,” Steege explains. “While acoustic analysis cannot replace microscopic surface inspection, it ensures robust and economical quality control for each individual component.”

Rooted in research, ready for industry

Several publicly funded projects laid the foundation for this development, including the EU-funded Syntecs project and the German BMBF-funded initiative Medius, which explores data-driven methods for laser process monitoring. Fraunhofer IWS implemented a fully functional demonstrator through internal funding from the Fraunhofer Performance Center Smart Production and Materials, with a clear focus on industrial application.

The institute offers industrial partners the opportunity to test the system in pilot applications or integrate it as an OEM component. “We see great potential for acoustic monitoring across industries – from high-precision structuring to robust welding processes,” Steege emphasizes. “Our strength lies in the combination of process-oriented sensor technology and intelligent software design geared at everyday industrial use.”

Next step: monitoring for welding and cutting

In addition to laser-based surface structuring, another team at Fraunhofer IWS, led by Dr. Axel Jahn, is transferring the principle of acoustic analysis to macro processing applications such as laser beam welding and cutting. These processes generate complex acoustic and optical emissions that directly reflect the quality of weld seams and cut edges.

The researchers capture data using high-dynamic microphones and high-speed cameras to monitor these processes. They first separate proper signals from background noise and link them to characteristic process states and quality indicators. In collaboration with the Fraunhofer Center Mid-Atlantic (CMA) in the United States, Fraunhofer IWS is developing a dedicated sensor platform and tailored data analysis algorithms. The system uses high-dynamic microphones and optical sensors that integrate seamlessly into industrial welding cells. Machine learning algorithms analyze the sensor data and reliably detect key patterns such as beam misalignment, spatter formation, or seam instability.

“Welding and cutting processes also produce acoustic signatures that reveal quality and highlight faults,” explains Jahn. “We design systems that capture these signals reliably – even in noisy environments. In the future, we aim to bring laser applications with sensor-based process monitoring into broader industrial use.”

Where Acoustic Monitoring Adds Value

Laser Micromachining:

Enables real-time quality control of functional microstructures (e.g., anti-reflective, hydrophobic) directly during processing.

Laser Beam Welding:

Monitors weld seam quality acoustically. Detects porosity, spatter, or unstable processes using characteristic sound signatures.

Laser Cutting:

Uses acoustic signals to confirm complete and clean cuts. Also identifies faults like dirty optics or incorrect parameters.

(Source: Fraunhofer IWS)

Schlagworte

CAMComputer Aided ManufacturingControlCuttingEmissionsLaserLaser BeamProcessingSoftwareWelding