The Starfire Hub – an initiative funded by the US Department of Energy to develop fusion energy solutions under the leadership of Lawrence Livermore National Laboratory (LLNL) – is pleased to announce the addition of five new members to its Diode Technology Working Group. Two German research institutes and three global leaders join the LLNL strengthening Starfire’s collaborative effort to advance the technology basis for inertial fusion energy (IFE).

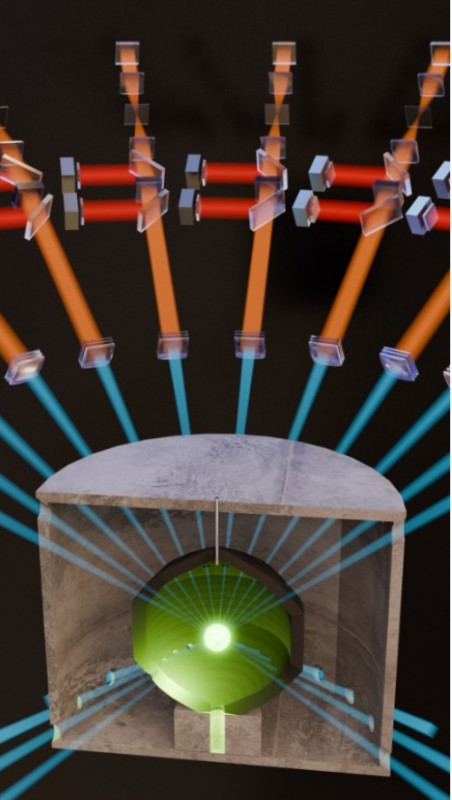

“We’re excited to welcome a distinguished group of organizations to the Starfire Hub. Their collective expertise will be instrumental in accelerating the development of diode technology needed to make inertial fusion energy a reality,” said LLNL’s Will Fenwick, Chair of the Diode Technology Working Group. Background: To make inertial confinement fusion (ICF) usable for power plants, fundamentally new plant concepts based on diode technology are required. Since December 2022, the National Ignition Facility (NIF) at LLNL has demonstrated in repeated experiments that it is possible to use lasers to ignite a fusion plasma from the hydrogen isotopes deuterium and tritium with energy gain. However, in the test facility, flash lamps are used to pump the world's largest and most powerful laser system. In future fusion power plants, this task will be performed by highly efficient diode lasers. With minimal energy input and high energy output, these must guarantee a frequency of 10 to 20 pump pulses per second (10-20 Hz) without overheating. The pump light supplies the energy needed to amplify the laser radiation to the megajoule range for igniting the fusion plasma.

Roadmap for next-generation high-power laser diodes

The working group, which has been expanded by five members, will define technical requirements, assess feasibility and drive innovation to support industry-wide progress in high-power diode technology. It will also push the convergence of requirements between IFE laser drivers and laser diodes. Further objectives that the members will be working on are a common definition of diode reliability for IFE as well as a standard for reliability testing of diodes in IFE applications. For the latter, interlaboratory tests to compare the performance of the diodes at several locations are planned, which will be coordinated by the working group.

Paul Crump, head of the High-Power Diode Laser Lab at the Ferdinand-Braun-Institut – Leibniz-Institut für Höchstfrequenztechnik (FBH) in Berlin, will lead the newly formed working group together with Will Fenwick from LLNL. Along with the FBH, another research partner, the Fraunhofer Institute for Laser Technology ILT in Aachen joins the Diode Technology Working Group. It had already been a member of the broader Starfire hub, along with Trumpf Photonics and Leonardo Electronics. New additions include three international companies in the field of diode laser technology: Coherent, Hamamatsu Photonics K.K. and Lumibird.

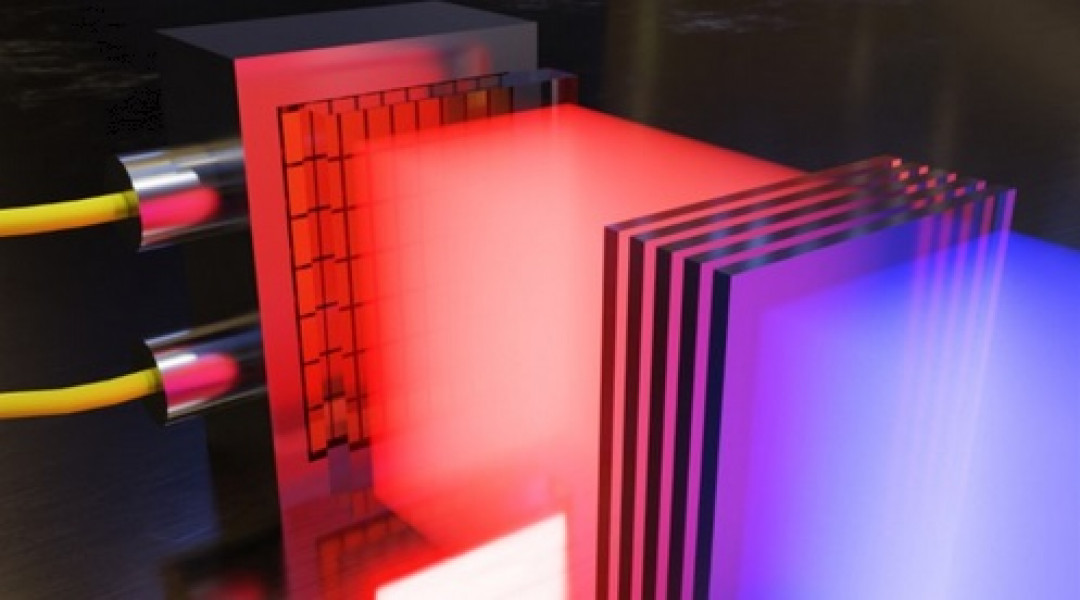

(Source: Fraunhofer ILT)

Schlagworte

DevelopmentDiode LaserDiode TechnologyEnergyHydrogenInternationalLaserResearchSolutions