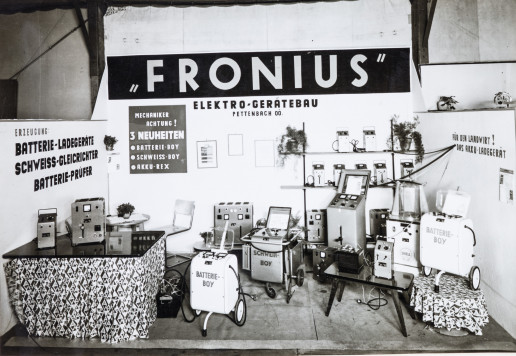

Founded in 1945 as a regional specialist repair shop for radio and electrical equipment, Fronius has grown into a global player in the industry over the past 80 years. Throughout its history, team spirt, perseverance and staying power have always been at the heart of the Austrian family business. It all started on June 20, 1945, when Günter Fronius officially advertised that he would be offering maintenance services for radio and electrical appliances out of a hotel. Not long after, the trained electrical engineer had a revolutionary idea: He built a device for recharging car batteries, allowing them to be used for longer. This first Fronius product was a big hit and was followed by innovative chargers for industrial applications such as forklift batteries.

“If you look at the conditions at the time, our beginnings came down to innovative strength, boldness and team spirit. Resources were in short supply, but that sparked my grandfather’s inventive spirit and drove him to make the best possible use of what he had to work with, to make it repairable and affordable for a broad sector of the population,” says Elisabeth Engelbrechtsmüller-Strauß, Fronius CEO and granddaughter of the company founder.

Driving renewable solar solutions

Just five years in, Günter Fronius expanded the company’s range to include welding transformers. This move laid the groundwork for Fronius to grow into a substantial, medium-sized industrial company. In 1980 Günter Fronius handed over the reins to the next generation, Brigitte Strauß and Klaus Fronius. They launched a programme of growth and international expansion that led to the founding of numerous subsidiaries all over the world – 37 in total today. Starting in 1992 Fronius also turned its attention to solar energy, which was considered alternative at the time but is now indispensable in the energy industry.

“Renewable energy is a driving force for us, so we are continually working on solutions that link up the electricity, heating, cooling, and mobility sectors to achieve our vision of 24 hours of sun,” says Engelbrechtsmüller-Strauß, who took over the management of the company from her mother and uncle in 2012.

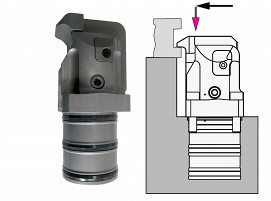

20 years of Cold Metal Transfer (CMT)

Through its products and solutions, the technology company has helped to drive economic progress worldwide, thus contributing to the growth of other companies, e. g. in the automotive industry. The 20th anniversary of Cold Metal Transfer (CMT) represents a key milestone in this context. By introducing this welding process, Fronius ushered in a paradigm shift in welding technology. For the first time ever, CMT made it possible to thermally join galvanized steel and aluminium sheets, as well as joining wafer-thin aluminium sheets from a thickness of 0.3 millimeters.

Solar energy and battery charging systems

Solar & Energy is moving closer to its goal of making the best possible use of solar energy as well as optimizing battery charging systems for intralogistics – based on the idea of the company’s founder and the very first Fronius product. While these two lines of business may appear very different at first glance, the company’s team of 7,000 specialists worldwide continues to pursue the same clear mission: Researching and controlling electricity as the fuel of the future. “And we want to make this a future worth living – for us and future generations,” says Engelbrechtsmüller-Strauß.

Research and innovation with a vision

Fronius will continue to research ways of converting electrical current as well as developing, producing and pushing forward with targeted solutions in this field. The managing director notes that certain things are set in stone: “No one really knows what the future will bring. But we will remain financially independent and continue boosting Austria’s standing as a business location – and thus value creation for our products in Europe. Our drive to research will be part of everything we do, always focusing on quality and user-friendliness.”

(Source: Fronius International GmbH)

Schlagworte

AluminiumAutomotiveBatteryBattery ChargingCMTCold Metal TransferControlElectricElectricityEnergyEVIndustryInternationalJoiningMAGMIGPowerPVRenewable EnergySolarTechnologyTransformationTransformersWelding