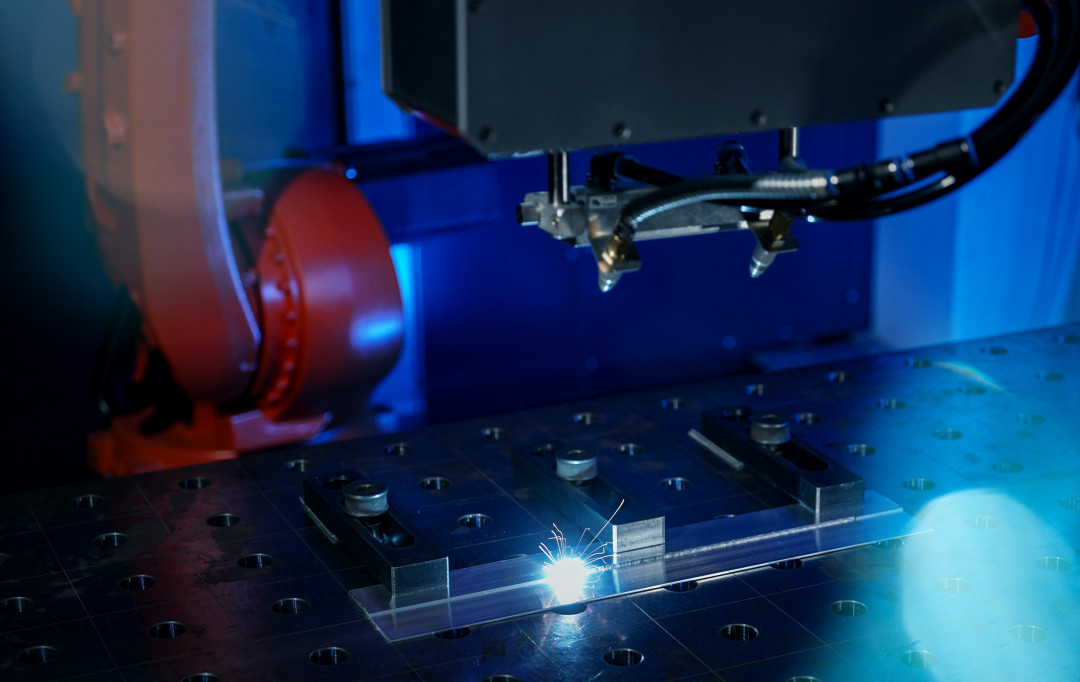

Blackbird Robotersysteme, manufacturer of system solutions for remote laser welding, has expanded its range of functions to include optical coherence tomography (OCT) for automated weld seam inspection. The fully inline-capable solution enables contactless detection and classification of seam defects in real time – without affecting cycle times or welding results. The combination of multi-stage inspection logic, PLC integration and flexible adaptability to different seam geometries makes the system a scalable tool for series production. The OCT Seam Inspection functionality is available from version 8.28 of the Blackbird RSU User Software and can be conveniently integrated via a software update.

The new OCT Seam Inspection feature provides users with a powerful extension for inline quality assurance in the welding process. Based on OCT, the seam geometry and surface defects are detected without contact, in real time, and without affecting process stability – even with an on-the-fly process design and at high-frequency oscillations of up to 1000 Hz. Seam Inspection is therefore completely cycle-time neutral and can be integrated directly into production without any time losses.

The seam inspection is based on a multi-stage evaluation model: individual OCT measurement lines are continuously recorded along the weld seam and the seam surface is automatically detected. Seam characteristics are calculated from this and checked for defined defect characteristics. Recurring or adjacent individual deviations are intelligently grouped together to form collective defects – for example, in the case of pores or holes. In addition, the overall quality of the seam is evaluated as a percentage in order to identify systematic defect distributions along the weld line. All limit values and minimum sizes can be configured individually for each defect type.

The solution currently supports the evaluation of fillet and lap welds at lap joints. The underlying architecture is open and can be flexibly adapted to new geometries and customer-specific inspection requirements. Combination with other OCT functions is also possible: Functions such as edge tracking or keyhole depth monitoring can be activated and operated together within the same sensor setup.

Direct process connection and transparent data communication

During the ongoing process, the system delivers standardized OK/NOK signals and associated error classifications directly to the higher-level control system. If defined tolerances are exceeded, programmable responses can be triggered automatically, such as stopping the welding programme or ejecting defective parts. At a later point in time, all measurement data, evaluations and score values can be made available via standardized interfaces, such as OPC UA. This can be used for quality assurance, traceability or statistical evaluations, among other tasks.

OCT-based seam inspection is designed for continuous industrial operation, highly scalable and requires little maintenance. The system does not require any additional light sources and can be easily integrated into existing manufacturing concepts. Additional evaluation logic and seam types can be added via software updates without hardware changes – future-proof, expandable, and efficient. The functionality is available from version 8.28 of the RSU User Software.

(Source: Blackbird Robotersysteme GmbH)

Schlagworte

AutomationLaserLaser Beam WeldingOCTOptical Coherence TomographyRoboticsRobotsSystem SolutionsSystemsWelding