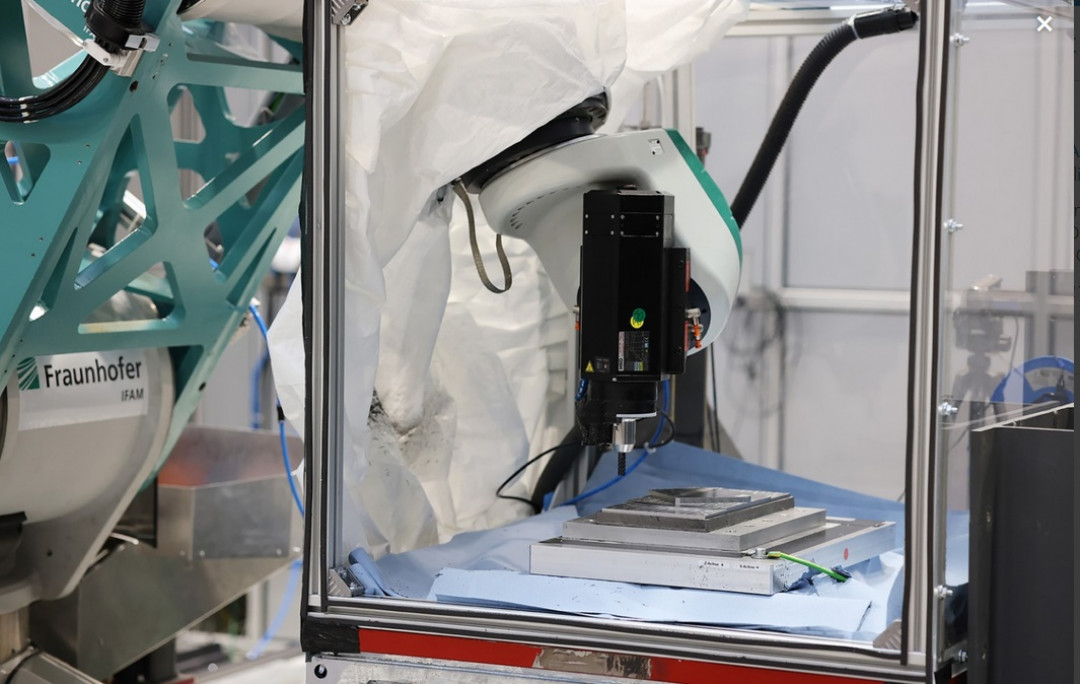

Fraunhofer IFAM in Stade has developed a technology together with Siemens to improve the dynamics and precision of industrial robots. This technology integrates intelligent, model-based control strategies with innovative drive technologies which are combined with a mechanical robot structure optimized by autonox Robotics. This development enables dynamic errors to be compensated for and vibrations to be effectively damped. This significantly improves path accuracy, even at high feed rates and complex path movements.

A particular advantage is the optimized disturbance rejection which ensures constant precision even with highly dynamic process forces. This drive concept therefore enables machining with higher material removal rates as well as the ability to operate with higher jerk settings, both of which lead to a significant increase in productivity.

Thanks to these properties, the Machine Tool Robot (MTR) closes the gap between classic industrial robots and machine tools. It is particularly suitable for demanding manufacturing processes, e.g., in the machining of harder materials, and open up new possibilities for automation technology as well as smart industry.

Alternative machine concept

Industrial robots enable an alternative machine concept, especially if they are used together with a workspace extension by means of a surface-moving platform or additional translatory axes, such as linear axes, or in combination with other robots. Compared to gantry systems or machine tools, this machine concept is much more space-saving and not economically tied to individual large components. In addition, there is no need for special foundations, which makes it easier to adapt production lines in future.

Wide range of applications

The combination of serial articulated arm kinematics with a linear axis provides many advantages over large gantry and special machines for processing. The smaller mounting space and the modular design of the linear axis make the system highly flexible. The use of two preloaded rack and pinion drives compensates for reversal effects and achieves a sufficiently high drive stiffness of the linear axis carriage for path-accurate robot processes. Due to the high structural rigidity of the linear axis, the influences on the robot accuracy are low despite the large lever arms to the load application point.

Model-based calibration of industrial robots and linear axes

A software application for model-based calibration developed at Fraunhofer IFAM in Stade – CaliRob – opens up a complementary technology for increasing precision: Due to unavoidable manufacturing tolerances, industrial robots exhibit individual deviations from the ideal system. These deviations can result in errors of up to several millimeters when approaching target positions in robot systems without knowledge of these deviations. In order to achieve the highest possible accuracies, industrial robots must therefore be calibrated according to requirements. A key element of the CaliRob application is a very extensive mathematical model that includes over 200 parameters to describe robot kinematics on a linear axis.

Perspectives

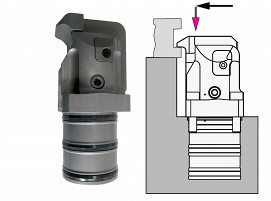

In the next step, the experts at Fraunhofer IFAM will test the new robot system together with their R&D partners Siemens as well as autonox Robotics in demanding industrial applications in order to further advance the potential of the technologies. For this, a robot spindle from Weiss Spindeltechnologie is used, which is designed for the high weight requirements.

Machine Tool Robots can be used for a wide range of applications: In combination with a linear axis, the spectrum ranges from machining tasks from the aerospace industry, such as lighter fiber composite structures and aluminium alloys, to the machining of harder materials, such as steel or titanium which are used, for example, in rail, commercial vehicle and shipbuilding as well as in the energy sector. Until now, it has not been possible to machine such components and materials in an industrially robust manner using industrial robots. In particular, the machining of harder materials using Machine Tool Robots appears to have a promising future.

Project funding

The Niedersachsen Ministry for Economic Affairs, Transport and Housing as well as the NBank funded the LuFo research project Robots Made in Lower Saxony 2 (RoMaNi 2; funding code: ZW1-80155399).

(Source: Fraunhofer IFAM)

Schlagworte

AerospaceAluminiumAutomationCuttingEnergyFiber CompositesManufacturingProcessingProductionRail Vehicle ConstructionRoboticsSteel