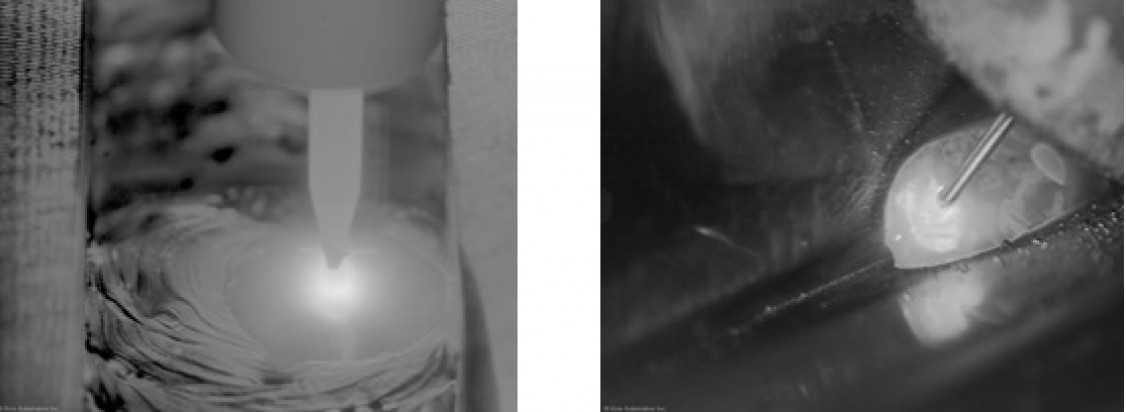

Xiris Automation announces the release of its NIR (Near Infrared) Weld Camera System with a 140+ dB High Dynamic Range (HDR) imaging capability with advanced NIR illumination that can be synchronized to the camera. Tailored especially for open arc welding processes where a clear view of the arc and surrounding background is needed, the NIR Weld Camera System delivers crystal clear views of the welding electrode, weld arc, melt pool and surrounding background. With its modular design of camera plus up to 3 remote LED light sources, the system can integrate with any welding automation equipment, providing high image quality for process research, additive manufacturing, welding education and welding production applications without the use of dangerous to eye lasers.

Using a NIR camera and NIR LED illumination together, the system generates stable, robust images of high contrast weld features that enables both manual remote monitoring as well as advanced Machine Vision analysis. The LED illumination module can be mounted remotely from the camera, providing flexible optical setups. Stable, high contrast images are key to making precise geometric measurements and defect detection of weld processes. Combined with Xiris’ AI-powered machine vision package WeldStudio, users can measure and track vital welding features or detect defects in their process to meet the demands of even the most challenging fabrication standards in use today. The NIR Camera System is suitable for integration into most types of weld automation systems, particularly for demanding GMAW and GTAW processes.

(Source: Xiris Automation)

Schlagworte

Additive ManufacturingArc WeldingAutomationstechnikEducationGMAWGTAWOpen Arc WeldingTestingWeld TestingWelding