You will find the company at the fair in Hall 3, Stand 3B12.

You will find the company at the fair in Hall 3, Stand 3B12.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

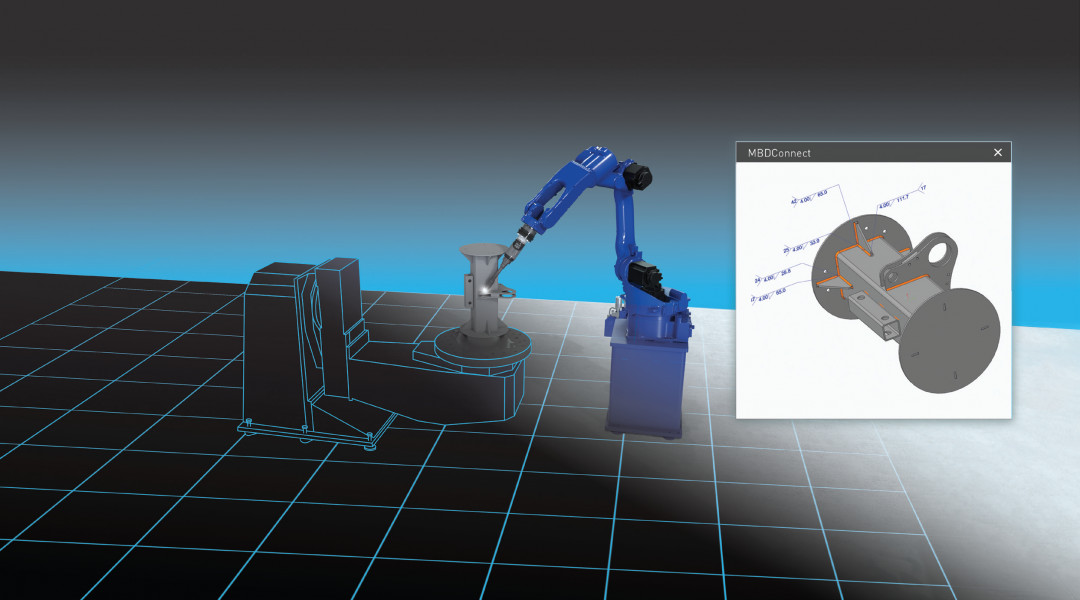

Visual Components 5.0 introduces improved robot offline programming (OLP) automation, enabling manufacturers to leverage model-based engineering with support for model-based definition (MBD) and product manufacturing information (PMI) for seamless design-to-manufacturing collaboration.

Automate with accuracy and consistency

Visual Components 5.0 extracts PMI from companion files or embedded metadata in supported CAD formats to automatically generate accurate robot toolpaths. This minimizes manual input and reduces interpretation errors.

Flexible across brands

Visual Components 5.0 enables easy programming across 22 robot brands with built-in post-processors. It automates robotic welding parameters application and robot path solving to avoid collisions. The new Fronius power source connector streamlines weld job management within the software.

(Source: Visual Components Oy)

Schlagworte

DigitalisationITProgrammingRobotRobotsSCHWEISSEN & SCHNEIDEN 2025Welding