Sie finden das Unternehmen auf der Messe in Halle 6, Stand 6F28.

Sie finden das Unternehmen auf der Messe in Halle 6, Stand 6F28.

SM70-MT – Electrodeposit-coating friendly welding wire

E-coating is a well-established technique in the automotive industry to protect car parts against corrosion, but its application on welded components can be problematic due to poor adherence onto silicate islands left behind on welds by the GMAW process.

Lacking solid E-coating protection, these spots may later act as initiators of rust development when vehicles are exposed to corrosive environments such as humidity, temperature changes, sea winds and de-icing salts. Removal of the silicates is an effective measure, but costly in highly efficient fabrication lines and therefore undesired. Hyundai Welding responded with the development of the E-coating friendly GMAW welding wire, the SM-70T.

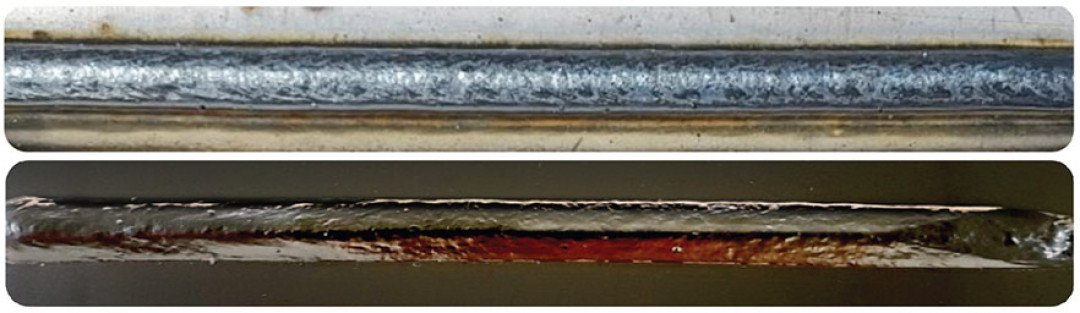

This product features ultra-low silicates formation and allows car parts to be E-coated without post-weld cleaning of the weld surface, as illustrated by the photo before and after E-coating. After extensive CCT – GMW 15357 testing (45 days) the weld samples rate 10/10, no sign of corrosion. SM70/MT also delivers virtually spatter-free welding along with excellent gap bridging ability – two other essential requirements of automotive fabricators.

(Source: Hyundai Welding)

Schlagworte

E-CoatingSCHWEISSEN & SCHNEIDEN 2023WeldingWelding Wire