The Sound of Perfect Coating

Potential for Environment and Health

Continuous Development and Improvement

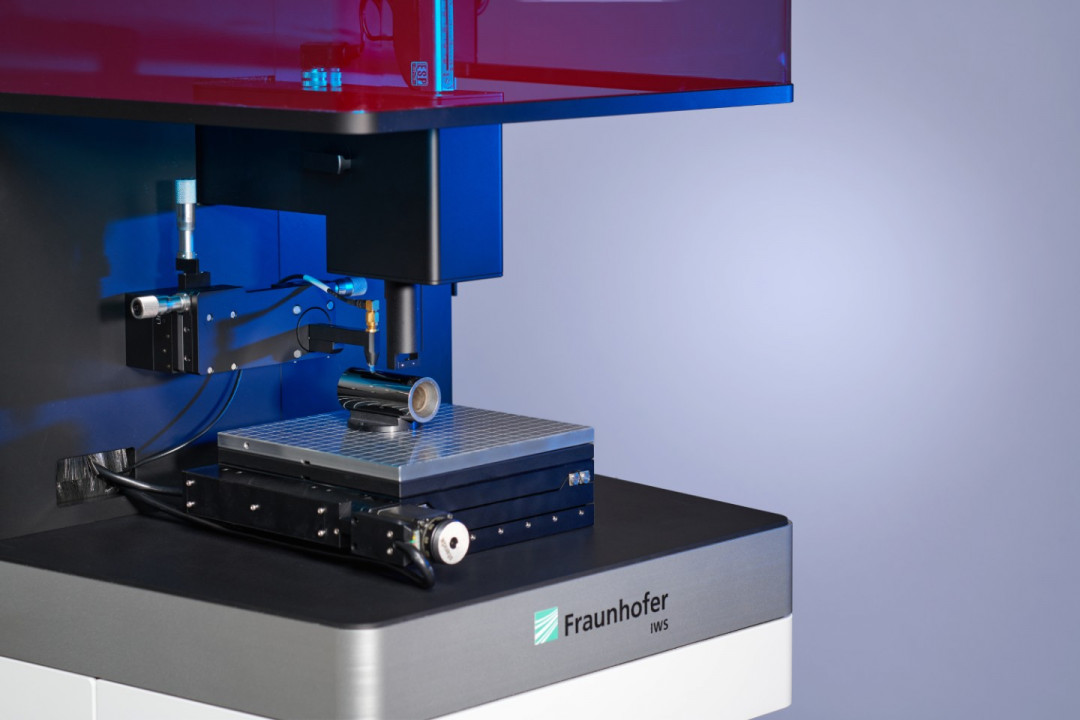

Early measurement systems of this type required complicated evaluation and were usually only operated by specialized scientists. Over the past 20 years, universities and non-university institutes have used those systems. Since then, however, Fraunhofer IWS has continuously developed and improved the technology and software and collaborated with partners to improve the design's user-friendliness. A cooperation between Fraunhofer IWS and the Chair of Technical Design at the Technical University of Dresden (TUD) contributed to this.

Fraunhofer IWS is currently developing further technological improvements to open up new fields of application for LAwave. For example, artificial intelligence can significantly improve the quality of analysis even further. A mobile LAwave measuring head also is on the agenda. Its design will allow the surface analysis of internally coated tubes, rollers, and other particularly heavy, large, or complex-shaped machine components that cannot be handled in a stationary device.

Fraunhofer will be displaying the current LAwave measuring system at the Control 2024 (April, 23 - 26), Hall 8, Booth 8201, ITSC Expo 2024 (April 29 - May 1), Booth 111 amd PSE 2024, September 2 - 5.

(Source: Fraunhofer IWS Press Release)