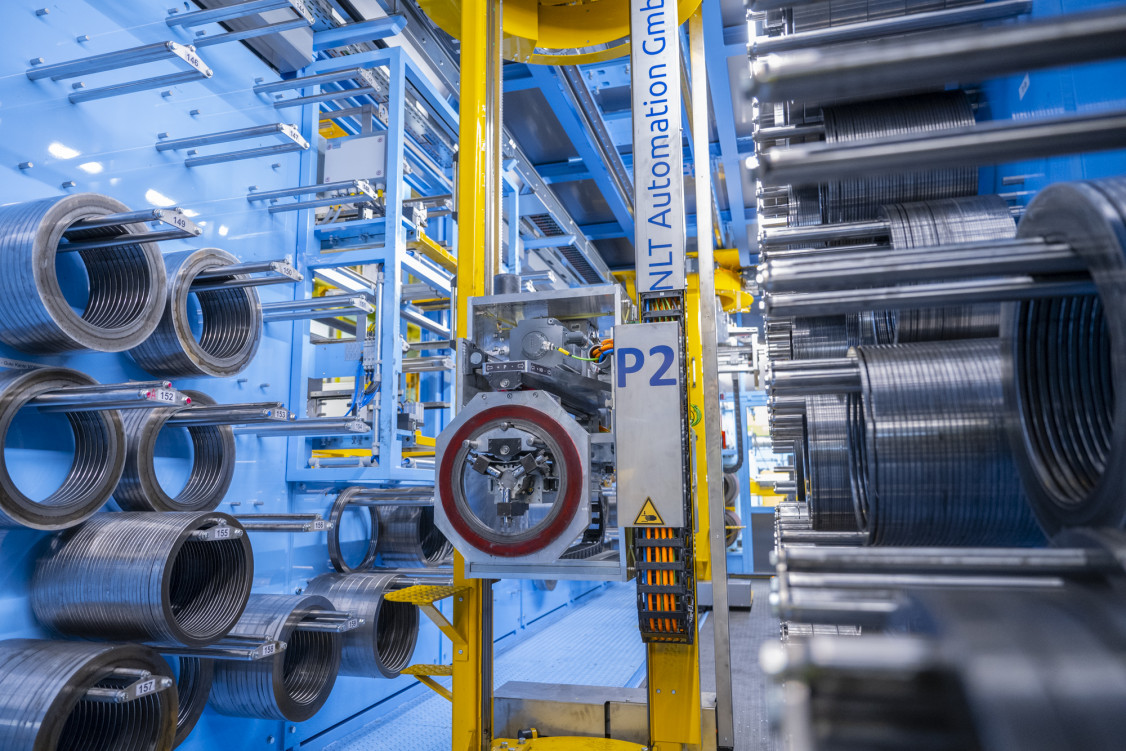

The Krefeld site of thyssenkrupp Materials Processing Europe, part of thyssenkrupp Materials Services, is one of three winners of this year's “Die Goldene Hand” prevention award presented by the German Social Accident Insurance Institution for the Trade and Logistics Industry (BGHW). On November 11, 2025, representatives of the company accepted the award at the ceremony in Mannheim. The award was given for the installation of a robot for assembling and disassembling circular knives for the slitting of steel coils. The fully automatic robot handles the loading of the systems at the company's Steel Service Center in Krefeld.

For slitting, the steel coils, which weigh several tonnes, are unrolled and cut into slit strips of various widths. Depending on customer requirements, circular knives in different arrangements are pushed onto a roller-shaped upper and lower shaft together with rubber rings as spacers. Until now, both the assembly of the tools and their disassembly after each coil cut were carried out manually, as was the inspection and cleaning of the knives after each use. This accumlulates to approximately twelve knife changes per shift and up to 24 kg per knife.

Since the knife assembly robot was installed in early 2025, the entire process is now automated and digitized. The robot receives all necessary information through a software interface, which specifies the required tools and their configuration, enabling it to assemble and disassemble them as needed. An integrated control unit measures the cutting edges of the circular knives using lasers after each use, and a washing system for the knives is also loaded by the robot. As a result, employees at the site are spared the physical strain of lifting heavy tool parts, and the risk of accidents caused by falling tools and injuries when cleaning the knives are avoided. Supported by appropriate training, employees now have fewer physical demands and are instead handling the robot.

“For us, the safety of our employees is our top priority. With our knife assembly robot, we can relieve our colleagues in their daily work and at the same time reduce the risk of accidents,” explains Martin Jacobs, site manager at thyssenkrupp Materials Processing Europe in Krefeld. “Of course, we are delighted that this project has been recognized by BGHW. Receiving the Prevention Award confirms our efforts to promote safety and automation in production.” “Die Goldene Hand” (The Golden Hand) is the BGHW's prevention award. It recognizes innovative ideas and projects for safety and health in the workplace and is awarded every two years.

(Source: thyssenkrupp Materials Services)

Schlagworte

AutomationAwardsCuttingMaterialsProcessingRobotRoboticsSteelWorkplace Safety