At this year’s EMO (September, 22 through 26) in Hannover, Germany, Schwäbische Werkzeugmaschinen (SW) will present two new products at its stand C05 in Hall 12. The Sfix system (Smart Fixture) is able to automatically assemble modular clamping fixtures for workpieces, enabling efficient and precise clamping even for small batch sizes. With the new BF 12-21D machine tool, SW is responding to the current trend in automotive engineering toward die-cast aluminum body parts.

In line with this year's trade fair motto, “Innovate Manufacturing,” Schwäbische Werkzeugmaschinen is presenting its response to current trends and requirements in production technology at EMO. “Especially outside the automotive industry, we see great potential for optimization in medium- and small-series production, which requires greater flexibility and modularity from manufacturers,” says Michael Kreuzberger, Product Manager at SW. “To address this, our new Sfix system revolutionizes clamping technology: through automation, it enables higher productivity even in production lines with smaller batch sizes.”

Modular and automated clamping

The Sfix system automates the assembly of the appropriate clamping technology for each workpiece – and provides users with a virtually unlimited number of clamping fixtures. At the core of the system is SW's patented Sfix plate, which features retractable pins that allow for flexible positioning of components. Various clamping modules can then be attached to these pins to build the individually required fixture.

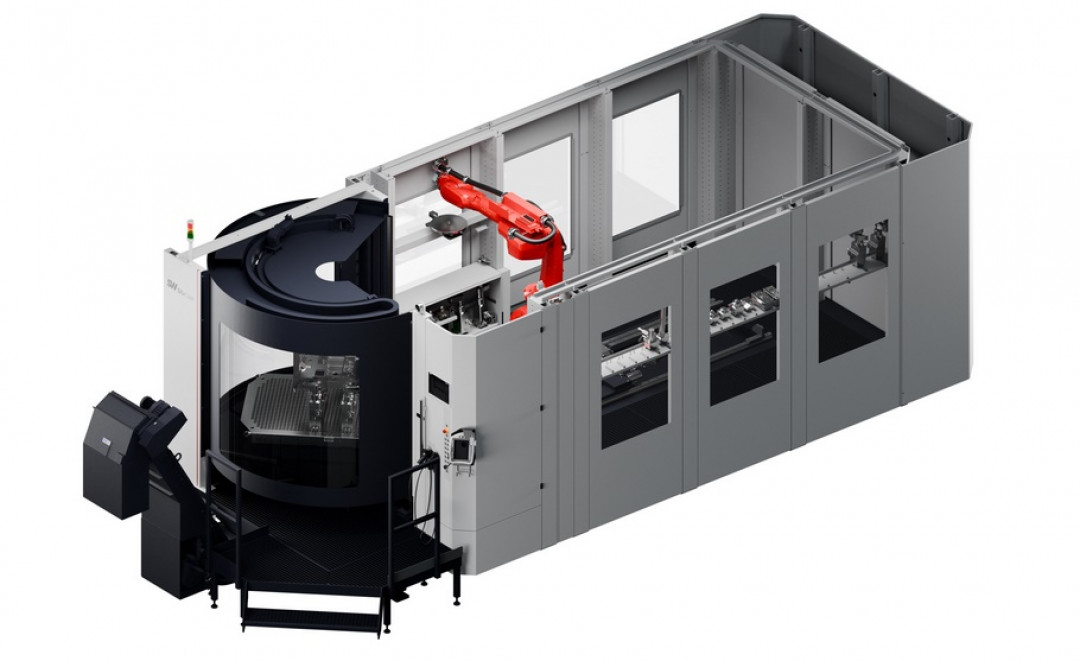

In the so-called S-cell the clamping fixture is assembled automatically. The cell is equipped with all necessary clamping components and workpiece carriers as well as a robot. Users only need to define the clamping points within the CAD model and configure the fixture setup. The smart, AI-supported system then generates a bill of materials for the required elements and automatically programmes the robot for assembly.

New machine for current trends

SW's booth at the trade fair offers solutions for small batch sizes as well as a new machine tool for high production volumes with the BF 12-21D. As part of SW's BF series, the system is specifically designed for the fast machining of frame and structural components. “In automotive engineering, we are seeing a clear trend toward the use of aluminium die-cast parts in vehicle body construction,” explains Kreuzberger. “These parts require less manufacturing precision than, for example, gearbox or stator housings. With the BF 12-21D, we offer an economical and dynamic machine concept for precisely these applications.”

The BF machine series differs from other SW machines in its structural design: it features a hybrid axis configuration, utilizing a linear drive for the X-axis, i while the Y- and Z-axes are driven by ball screws. SW also relies on proven twin-spindle technology to easily meet high productivity requirements: with two three-axis units and one spindle per working area, the BF 12-21D can replace two conventional single-spindle machines – and achieve higher output with a smaller footprint. When components are changed in one working area, the second spindle in the other working area can be used to achieve even higher productivity.

(Source: Schwäbische Werkzeugmaschinen GmbH)

Schlagworte

ApplicationAutomationAutomotiveCADDesignEMOExhibitFairIndustryManufacturingMaterialProductionRobotRobotsSolutionsToolsTrade FairTrendTrends