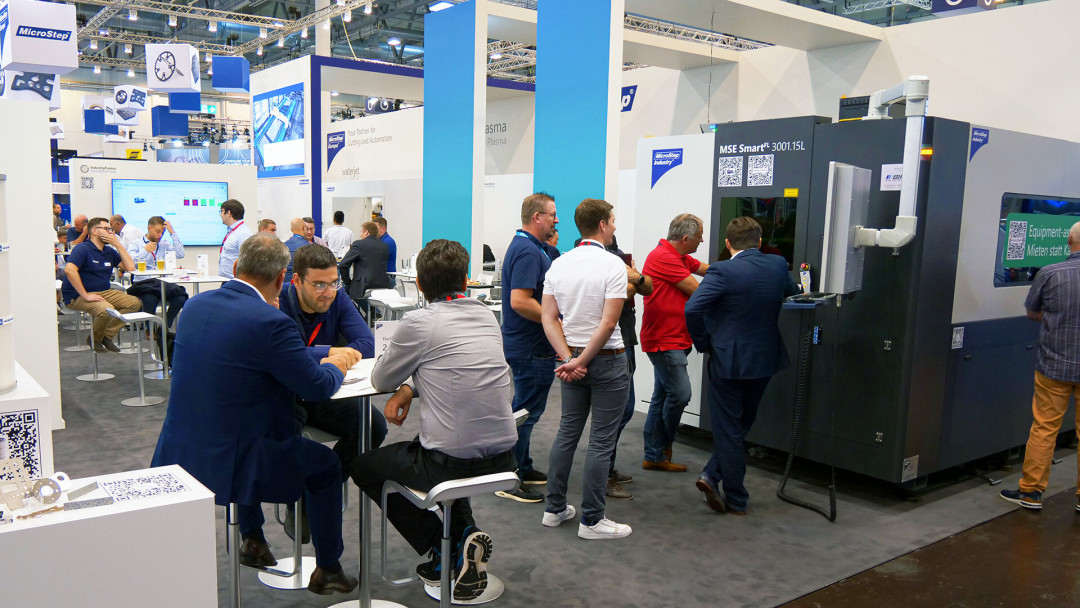

At SCHWEISSEN & SCHNEIDEN 2025, the IndustryFusion Foundation (IFF) will be presenting numerous innovations relating to the cross-manufacturer open-source networking solution IndustryFusion-X in Hall 6, Stand 6D22. A cooperation agreement with eco – the leading association for the Internet industry in Europe – will also be signed at the start of the trade fair. In addition, the foundation, together with Messe Essen and the German Association for Welding and Related Processes (Deutscher Verband für Schweißen und verwandte Verfahren e.V.), will present the IF Digital Award for the first time at the trade fair, which honours innovative digitalisation solutions.

Igor Mikulina, President of the IFF Foundation Board: ‘With IndustryFusion-X, we are creating a cross-manufacturer data space of the future for continuous, intelligent networking of industry.’

Numerous new innovative solutions have now been developed around this IndustryFusion-X data space – the operating system for Industry 4.0 – and will be presented at the trade fair.

X-Share Cloud Manufacturing

Based on IndustryFusion-X, the data space for Industry 4.0, cloud manufacturing is becoming a reality: Production factors, capacities and technologies are digitally networked across production lines. In this way, the entire manufacturing process is linked, managed and operated independently of location. As a result, production factors can also be shared across companies – the goal is to achieve full economic utilisation of all production factors involved in the manufacturing process and thus optimise sales and profits.

AI-supported assistant for production

Xana is an AI-supported assistant for machine operators that answers questions about operation, maintenance or fault diagnosis based on technical documents. The solution is based on open language models and is fully embedded in the IndustryFusion-X platform, which provides standardised machine data via data rooms.

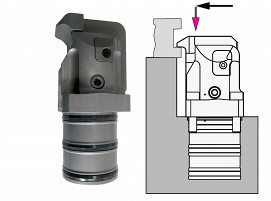

Rent instead of buy – without investment risk

With IndustryFusion-X, CNC production systems, for example, can be used with virtually no investment for the first time – thanks to the innovative Equipment-as-a-Service model. The monthly rates are dynamically adjusted to the actual utilisation of the machine, which means maximum flexibility and cost control for the user. This makes this technology accessible to smaller companies, with no capital commitment or financing risks.

EU-compliant digital product passport

EU-compliant digital product passports can be created and managed with FusionPass – fully integrated into the supply chain. The solution is designed for traceability, compliance and transparency on a large scale – a prerequisite for measuring the carbon footprint in the interests of a sustainable economy, among other things. Whether machines, cosmetics, furniture, fashion or toys – every product can be made digitally accessible via FusionPass and IndustryFusion-X. This creates traceability, enables new services and establishes a connection to the Web3 economy.

In addition, the IndustryFusion Foundation (IFF) will sign a cooperation agreement with eco – Association of the Internet Industry at the SCHWEISSEN & SCHNEIDEN trade fair. With around 1,000 members, the eco association is considered one of the leading organisations in the Internet industry in Europe.

Igor Mikulina: "The digital transformation of industry requires strong partnerships. With the eco association, we are gaining an experienced and innovative partner who shares our vision of open, interoperable and secure industrial platforms. This cooperation is a milestone for the future of networked production."

(Source: IndustryFusion Foundation)

Schlagworte

CloudCNCCuttingDataDesignFairIFFInnovationInternetITKISCHWEISSEN & SCHNEIDEN 2025SolutionsTechnologyTrade FairWelding