Modern steel construction increasingly demands highly customized designs, tight manufacturing tolerances and rapid project execution. To remain competitive in the welding and fabrication sector, companies must achieve maximum operational flexibility while minimizing resource expenditure. However, this objective is difficult to realize in light of the ongoing shortage of qualified welding personnel across the industry.

Skilled welders play a critical role in manufacturing, responsible for fabricating, joining and repairing components in accordance with stringent quality standards. Their work has traditionally required exceptional manual precision, comprehensive technical understanding, sustained concentration, and a keen attention to detail in order to ensure compliance with safety regulations and deliver structurally sound welds. Today, these competencies alone are no longer sufficient.

Welding in transition

Today’s welders also need to know about digital welding machines, documentation systems, occupational health and safety, how to protect their health and new materials. “Welding tasks change on a daily basis now, so welders face the challenge of new materials, changing seam profiles or different components every day,” explains Michael Eisterhuber, Product Line Manager at Fronius International.

Small and medium-sized companies (SMEs) particularly affected by skills shortage

Although large industrial companies often have their own training centers or find it easier to attract international skilled workers, small and medium-sized enterprises are increasingly coming under pressure. Experienced welders are gradually retiring with no one to take their place. Many young people avoid manual jobs, often due to outdated preconceptions or a lack of information about modern working conditions. For example, there remains a perception that welding poses significant safety hazards, despite the implementation of comprehensive occupational health and safety standards that have been in place for many years. However, automation is not a sure-fire success. Although cobots have become more affordable, acquisition costs are still a factor to be considered. The chosen solution must be appropriately scaled to the company’s operational capacity and compatible with its specific product portfolio.

Versatile welding machines create flexible solutions

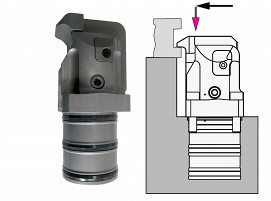

Small and medium-sized businesses especially need smart, scalable solutions – tools that are easy to use, quick to install and truly reduce workload without adding unnecessary complexity. “This is precisely where our new Fortis welding machine series comes in,” asserts Eisterhuber. Fortis was developed as a flexible tool for everyday welding work. The product range contains devices in the 270 to 500 A categories, either as compact all-in-one systems or as split versions with an external wirefeeder.

“No matter which variant you opt for, all compact models can be equipped with our proven functions such as pulse welding, SynchroPulse, stitch welding, TAC tacking function, HotStart and anti-stick,” explains Eisterhuber.

With up to 240 welding characteristics that have been specially optimized for steel, stainless steel and aluminium, Fortis can be used for applications such as vertical-up seams, root passes or thin sheet metal joints. Ideal for vertical-up seams: A Pulse/Standard mix is now also available. Combining these two processes makes it possible to achieve up to 40 % higher welding speeds without any oscillating movements.

The Fortis is available in multiple configurations to accommodate different operational requirements. The compact model can be equipped with an external wire feeder, while the Duo variant supports simultaneous use of two wire spools and two welding torches on a single unit.

The Extended (XT) variant of the Fortis is an energy-efficient all-rounder for three-phase mains voltages from 200 to 600 V and single-phase operation up to max. 320 A including CEL mode. As a result the XT machines are perfect for worldwide use, save energy thanks to their higher power factor, and offer an additional higher output characteristic curve for even greater welding performance.

Versatility

“Discussions with our customers clearly show that smaller manufacturers do not need complex automated lines of equipment. They want space-saving solutions that can be integrated quickly, are easy to use and are highly flexible,” summarizes Eisterhuber. In smaller workshops, every machine counts as two “so it makes sense to draw on multifunctionality.” The all-in-one Fortis variants, available up to 500 A with Multiprocess functionality, support MIG/MAG, TIG, and MMA welding, covering all standard processes.

Shortage of skilled workers requires intuitive technology

Even the most advanced welding machines are ineffective without skilled operators. Modern welding systems must be designed for rapid adoption, enabling users to operate them efficiently with minimal training.

Fortis features a 7-inch color display with dynamic visualizations, self-explanatory graphics and a multilingual menu with over 30 languages making its operation intuitive even for inexperienced users. Three robust rotary and push buttons give users precise control, even when wearing welding gloves.

(Source: Fronius Deutschland GmbH)

Schlagworte

AluminiumAutomationCobotsConsumablesMAGManufacturingMIGMMARobotsSkilled Labour ShortageSkilled WorkersSteelTIGWelderWeldingWire Feeder