Gas-shielded metal arc welding and the cause of weld spatter

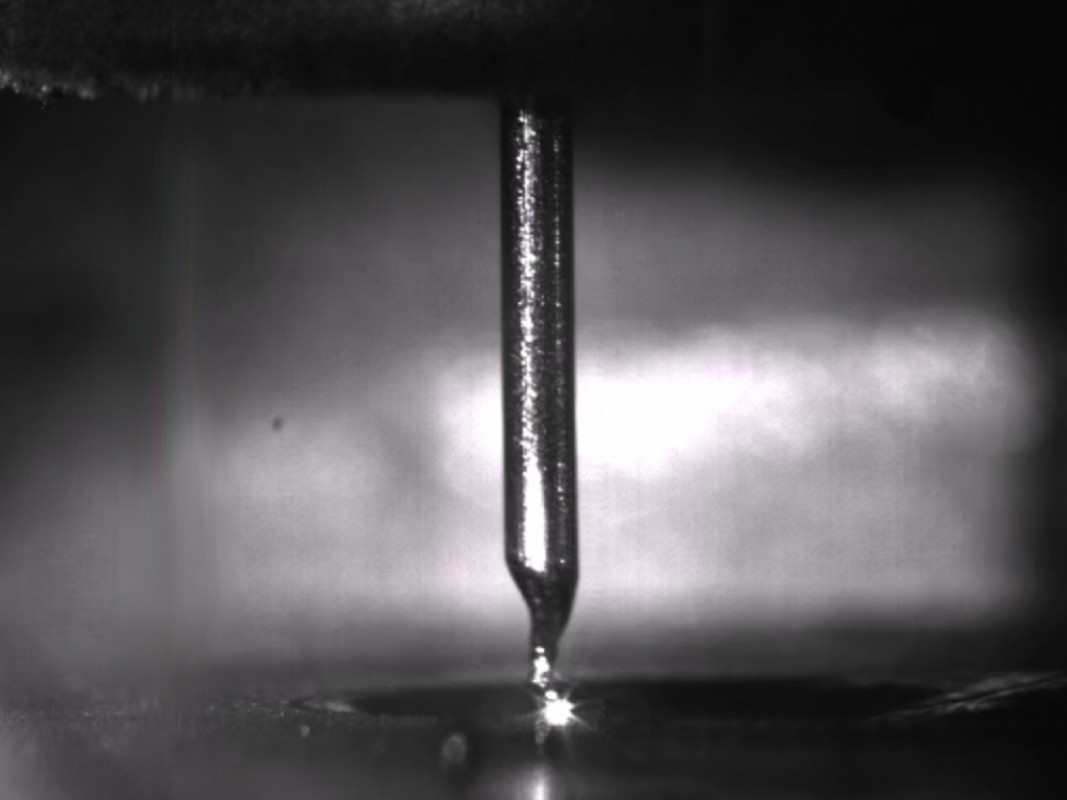

Unlike TIG or plasma welding, GMAW welding always produces weld spatter. The cause of weld spatter is related to the type of arc used. The three most common arc types are short-circuit arc, spray arc, and pulsed arc. They are used in over 90 percent of all MIG/MAG applications. The characteristics of these arcs determine the amount of spatter produced during welding.

Read the blog article Causes of weld spatter: GMAW welding and electric arc by Abicor Binzel Managing Director Prof. Dr. Emil Schubert to learn the reasons for the formation of weld spatter and how you can counteract it with the right technique.

Learn about the characteristics of the three most commonly used arc welding types and which applications they are best suited for. Since weld spatter cannot be completely avoided during GMAW welding, you will also find tips for preventing spatter adhesion.

Read the blog article “Causes of weld spatter: GMAW welding and electric arc“

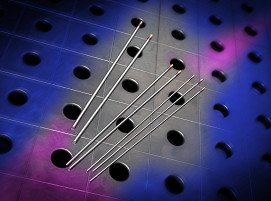

(Source: Alexander Binzel Schweisstechnik GmbH & Co. KG)

Schlagworte

GMAWPlasma WeldingPulsed ArcShort-Circuit ArcSpray ArcTIGWeld SpatterWelding