You will find the company at the fair in Hall 2, Stand 2B25.

International

21.07.2025

“Exhibitors announce”: The company mentioned in this article is an exhibitor at SCHWEISSEN & SCHNEIDEN 2025.

You will find the company at the fair in Hall 2, Stand 2B25.

You will find the company at the fair in Hall 2, Stand 2B25.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

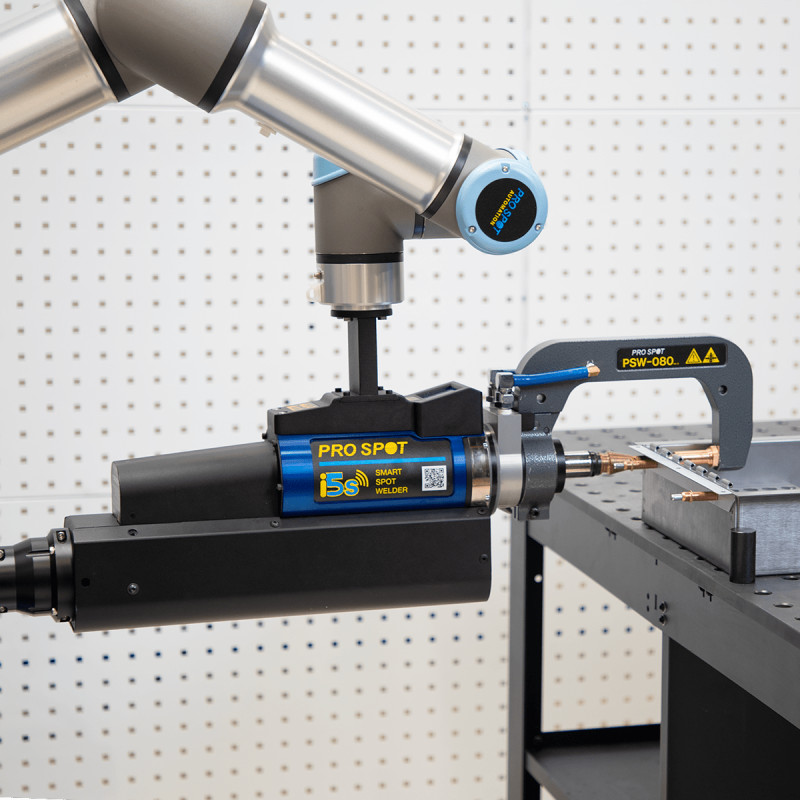

The handheld spot welder has been seamlessly integrated into a safe, easy-to-use Cobot automated welding workcell.

Key features:

- Auto weld, sense material thickness, resistance to adjust the weld profile automatically.

- Built in library for materials, weld caps, thickness stackups for semi-auto mode.

- Intuitive touch screen interface, with on-board training and user manuals, both in Video and PDF form.

- Repeatable, reliable welds, with complete data capture of welding and machine data.

- Connected: WiFi enabled keeps weld control software up-to-date. Ability to export data logs to email via WiFi for the ultimate in traceability and process control.

Automation:

- Easy to teach welding positions

- Unlimited number of recipe/job creation. Create, edit, Ssave and soad welding jobs with repeatable, traceable positions.

- Synchronized log of welding position with weld schedule and datalog.

- Cobot safe to work around humans without costly and awkward machine guarding.

Benefits:

- Keeps manufacturing process in control: reliable, consistent and traceable results

- Increase in production while saving labor and technician time

- Future proof investment with wireless factory updates

- Improves worker safety and reduces liability risks.

(Source: Pro Spot Deutschland GmbH)

Schlagworte

CobotControlLaserSCHWEISSEN & SCHNEIDEN 2025SoftwareSpot WeldingWelderWeldingWorkplace Safety