New software release permits greater flexibility in product design and offers online feedback

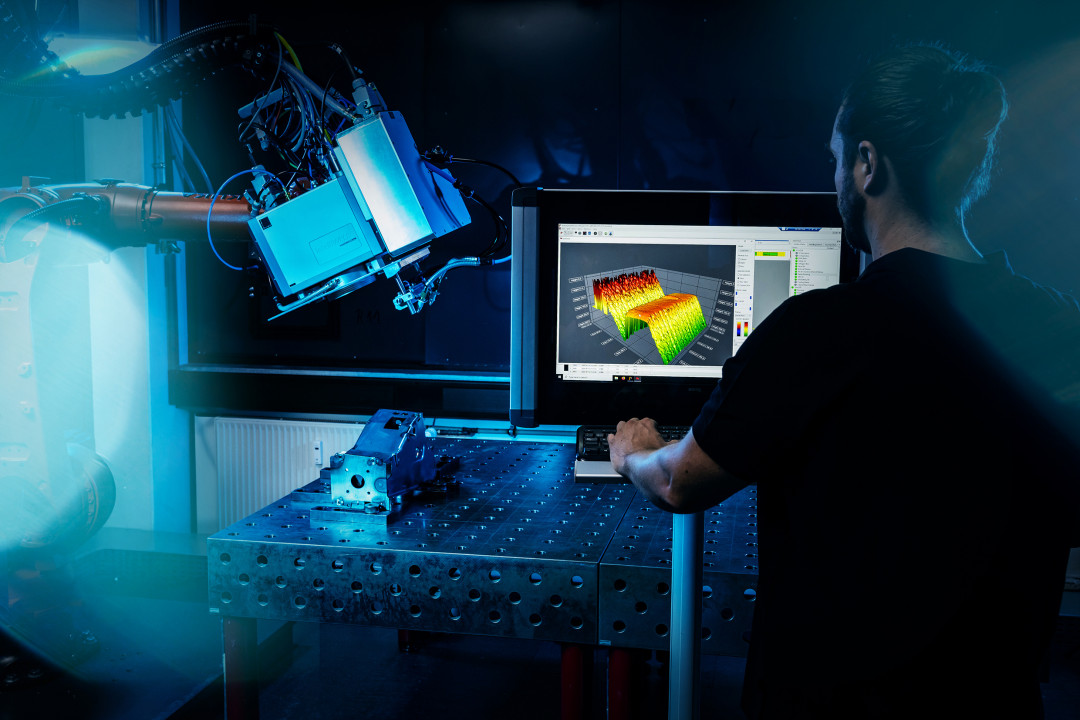

Blackbird Robotersysteme GmbH, manufacturer of system solutions for remote laser welding, has significantly advanced its award-winning solution for OCT edge tracking. As part of a new software release for edge tracking via optical coherence tomography (OCT), Blackbird presents a new feature developed specifically for the complex requirements of modern welding applications. The solution can now be used in an even broader range of applications and can respond to and communicate about various faults. In this way, the update supports flexible and tailored welding processes and sets new standards for production automation.

The requirements for edge tracking with OCT have evolved rapidly. Initially developed in collaboration with OEMs as a solution for tracking the edges of fillet welds at lap joints in the body-in-white segment, Blackbird's technology has encountered increasing challenges with the emergence of new joint geometries, particularly those arising from the specific requirements of new fields of application, such as agricultural and construction machinery. Blackbird's OCT technology, which is subject to increasingly complex requirements as remote laser welding penetrates deeper into the market, is impressive for its ongoing adaptability, so it can provide optimal support for specific use cases.

The new release significantly expands on the features of the Blackbird OCT solution, which offers optimized edge tracking options for a wide variety of joint types that are in demand in modern welding applications. In addition to proven edge tracking for fillet welds at lap joints, the system now also supports precision edge tracking for T-joints, corner joints, edge joints, and butt joints. This means a single solution can be used for reliable welding of a broad range of components going forward. Users can design their components independently of certain joint geometries without compromising on the precision or robustness of the process.

Detecting errors before they occur

This release's integrated quality feedback, which occurs in parallel with edge tracking, is another notable feature. Depending on the gap size detected, the system can respond to ‘unsuitable’ welding conditions on a case-by-case basis. For instance, the new feature automatically deactivates the laser power or internally stops the welding program if defined limits are exceeded. These predefined responses enhance the safety and quality of the welding process and enable smooth integration into automated production lines, along with the implementation of targeted repair strategies. RSU software versions 8.20.0 and higher have been updated with new features that will allow users to process a wide range of components on a single production line with efficiency and precision.

(Source: Press Release Blackbird Robot Systems)

Schlagworte

AIAMAutomationKILaserLaser WeldingOCTRobotRoboterRobotersystemeSoftwareWelding