You will find the company at the fair in Hall 3, Stand 3D68.

You will find the company at the fair in Hall 3, Stand 3D68.

![SCHWEISSEN & SCHNEIDEN 2025 [EN]](/images/frontend/journals/dvs-sus_sm.png)

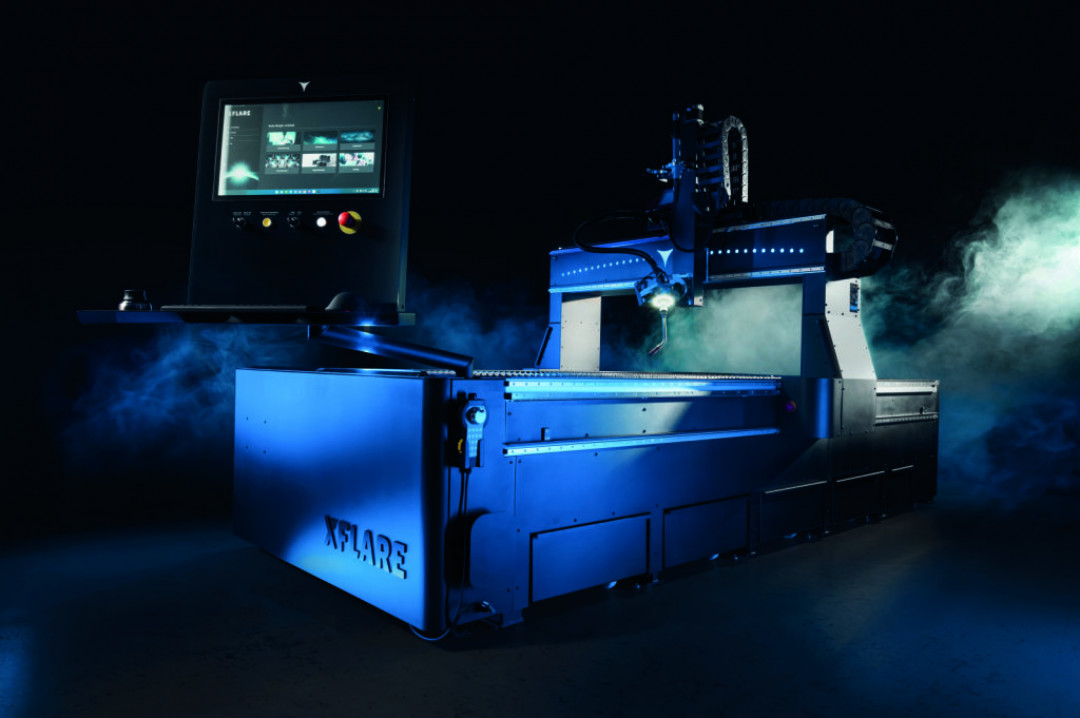

With Xflare, Xtraction introduces a compact, integrated system that combines welding and cutting in a single platform. This 2-in-1 solution automates key metalworking processes, replacing manual, experience-based workflows with structured, digitally supported operations.The system addresses industry challenges such as increasing quality requirements, skilled labor shortages, and the need for more efficient, sustainable production. XFLARE features a fully capable welding robot and a high-precision CNC cutting unit, enabling accurate cuts and high-quality weld seams across a range of workpieces.

Equipped with intelligent sensors and automatic process recognition, XFLARE adapts to varying components and production conditions. Real-time data acquisition supports process reliability, traceability, and automated quality assurance. The result is reduced welding time, minimized rework, and consistently reproducible output. Built-in assistance systems and automatic parameter adjustments further ease the workload for skilled personnel.

Designed for flexibility, Xflare enables small and mid-sized manufacturers to produce parts in-house, cost-effectively and with greater autonomy. The combined functionality allows companies to expand production capacity, improve quality control and enhance operational efficiency.

(Source: Xtraction GmbH)

Schlagworte

AutomationCNCCuttingEfficiencyIndustryManufactureMetalMetalworkProcessProductionRobotRobotsSCHWEISSEN & SCHNEIDEN 2025SystemWelding