The majority of employees in Germany believe that robot deployment in factories will ensure the country’s competitiveness. Three out of four are convinced that robotics can help alleviate the effects of skills shortages. Around 80 % would like robots to take on hazardous or repetitive tasks. These are the findings of the 2025 automatica Trend Index. It is based on interviews with a total of 5,000 employees from five countries.

Germany doubles number of robots

Improving the competitive positioning is among the most pressing tasks of the new federal government. And the industry is at the center of this effort. Germany has doubled its number of robots per factory worker within four years (2019-2023). According to the International Federation of Robotics (IFR), China, on the other hand, with 470 units per 10,000 employees, advanced to second place worldwide in 2023. Germany is down to fourth place with 429 and Japan comes in fifth with 419 units.

Robots take on unpopular jobs

The automatica Trend Index is based on interviews with more than 1,000 employees each in Germany, Japan, China, USA and the United Kingdom. According to the survey, around three out of four respondents in Germany feel that robots can help improve competitive positioning and keep industrial

production in their own country. The Trend Index found that respondent approval is even stronger in China: Around 80 % see the positive effects for domestic industries. In contrast, it is only two out of three in the US.

Robots help with skilled worker shortage

The lack of specialists is a key driver of automation adoption. 75 % of respondents feel that robotics can provide solutions in this context. The automatica Trend Index produced particularly high approval figures when respondents were asked whether robotics and automation would improve the

future of work: A vast majority wants to hand over dirty, monotonous, and dangerous tasks in factories to robots. 85 % are convinced that robots lower the risk of sustaining injuries when performing dangerous work. And 84 % consider robots a key solution for handling hazardous materials.

Finally, 70 % of respondents expect that robots will enable elderly professionals to postpone their retirement.

automatica 2025: solutions for SMEs

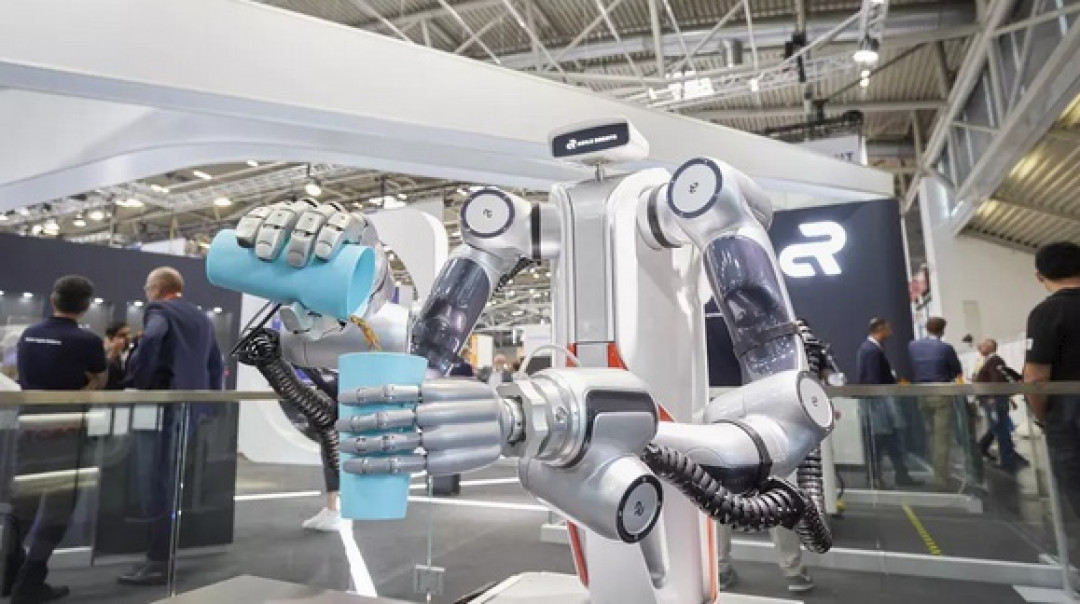

“Robotics and automation have great potential in tackling the lack of specialists and improving work environments as they take on unpopular tasks”, says Dr. Dietmar Ley, Head of the VDMA Robotics + Automation Association. “And it has never been easier for companies to benefit from industrial robotics. Robot development is experiencing rapid technological progress in terms of usability. Setting them up and operating them will soon be as easy as using smartphones and similar devices.”

Dr. Reinhard Pfeiffer, Managing Director of Messe München, emphasizes that robotics and automation are not job killers but secure jobs and strengthen the industry’s competitive positioning. Dr. Pfeiffer comments: “The German industry is facing a multitude of challenges. At automatica, around 750 exhibitors from about 40 countries present workable solutions across six exhibition halls. Being

a leading international marketplace for automated and smart production, automatica is the perfect platform to engage in knowledge transfer and get inspired.”

The trade fair is held at the Munich, Germany, exhibition center from June 24 through 27, 2025.

(Source: Messe München)

Schlagworte

AIARAutomaticaAutomationDevelopmentExhibitExhibitionFairIndustryInternationalITManufacturingProductionRobotRoboticsRobotsSkillsSMETradeTrade FairTrendWork